The Egg Processing Equipment Market is undergoing a striking transformation, shifting from traditional production methods to a high-tech, sustainable future. As one industry expert noted, “The next era of egg processing is about marrying precision technology with ethical production to meet evolving consumer demands.” This next-gen outlook underscores a market redefined by innovation, sustainability, and consumer-driven customization between 2024 and 2028.

From concerns over Salmonella contamination to the rise of plant-based alternatives, the egg processing sector is experiencing a profound pivot. The market is no longer solely focused on volume but on quality, safety, and ethical sourcing. Today’s players are deploying robotics, automation, and innovative processing techniques to accelerate production times and safeguard food safety — while also addressing vegan and health-conscious consumer segments.

For more details about the industry, get the PDF sample report for free

The journey of the egg processing equipment market reveals distinct phases:

2019: Traditional mechanical systems dominated, focusing primarily on pasteurization and basic egg product forms like liquid and dried eggs. Automation was limited, and regional growth was uneven, with North America and Europe leading.

2023: The industry embraced advanced automation, robotics, and heat-treatment innovations to reduce contamination risks. Emerging demand for functional egg products, such as low-cholesterol and allergy-friendly options, influenced equipment development. APAC emerged as a powerful growth region, accounting for 43% of market growth.

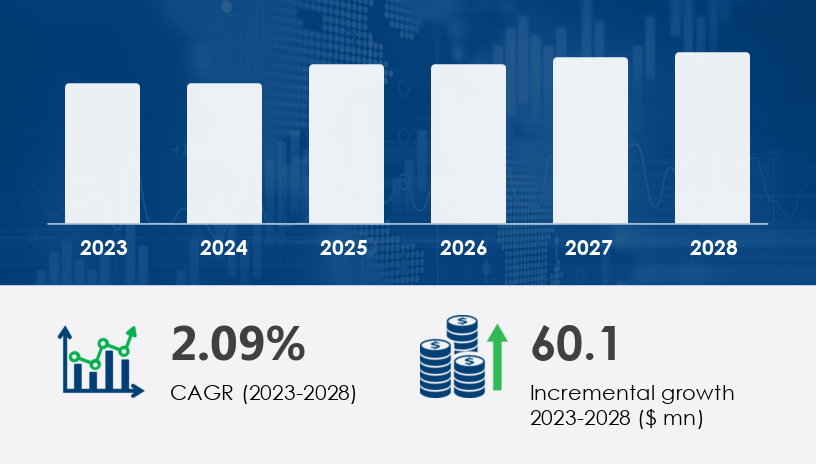

2024–2028 (Projected): The market is expected to increase by USD 60.1 million at a CAGR of 2.09%. A surge in demand for liquid egg products, vegan alternatives, and innovative processing technologies will reshape competition and regional leadership, especially across North America and APAC.

Legacy Disruption: Traditionally limited by short shelf life and contamination risks, liquid egg processing relied heavily on pasteurization and refrigeration.

New Strategy Emerging: Integration of ultra-pasteurization, aseptic packaging, and robotics for efficiency and quality. Automation streamlines processes like homogenization and palletizing.

Analyst Insight: Automation and robotics in liquid egg processing reduce contamination risk and labor costs, boosting production efficiency.

Business Case: A leading food service supplier implemented robotic palletizers and ultra-pasteurization lines to double liquid egg throughput while reducing spoilage by 20%.

Key Stats: Valued at USD 218.5 million in 2018 with steady growth expected; shelf life extended from 2–6 days through advanced packaging technologies.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report

Legacy Disruption: Historically constrained by inconsistent quality and limited functional properties due to less sophisticated drying and freezing techniques.

New Strategy Emerging: Adoption of freeze-drying, enzyme modification, and shockwave technologies to preserve nutrients and enhance product shelf life.

Analyst Insight: Innovative drying methods now enable the production of allergy-friendly, high-protein egg powders catering to health-conscious consumers.

Business Case: A top manufacturer used enzyme-modified dried egg powders to launch a new line of allergy-friendly baking ingredients, capturing 15% market share within two years.

Key Stats: Growing demand for functional egg products, including low-cholesterol and allergy-friendly options; shockwave tech reduces energy consumption during processing.

Legacy Disruption: These core machines were traditionally bulky, energy-intensive, and limited in precision heating.

New Strategy Emerging: Shockwave technology offers direct heat application without heat transfer surfaces, reducing water and energy usage and improving homogenization quality.

Analyst Insight: Shockwave tech revolutionizes heat treatment, enabling uniform mixing and extending shelf life while reducing operational costs.

Business Case: A leading equipment supplier integrated shockwave pasteurizers into their portfolio, helping clients cut energy consumption by 30% and boost production speed by 25%.

Technological Innovation: Companies investing heavily in automation, robotics, and novel processing methods (like shockwave tech) are gaining a decisive edge.

Consumer Demand for Sustainability: Health-conscious and ethical consumption trends force manufacturers to develop low-cholesterol, high-protein, and plant-based egg alternatives.

Regional Expansion and Biosecurity: APAC’s rapid market growth and North America’s focus on biosecure, sustainable farming practices create competitive battlegrounds.

The Egg Processing Equipment Market is witnessing robust growth driven by increasing demand for efficient and automated solutions such as egg breaking machines, egg separators, and egg cracking devices that streamline liquid egg processing and improve productivity. Key equipment like pasteurization equipment, including inline pasteurizers and batch pasteurizers, ensure food safety and extend shelf life, while sterilization units and high-pressure processing systems enhance microbial control. Advanced technologies such as shockwave technology and pulsed electric field are being integrated into egg washing units and egg yolk processors to improve quality and hygiene. Automation is further enhanced by programmable logic controllers and supervisory control systems that coordinate conveyor systems, egg loading machines, and automated egg graders for efficient egg sorting and inspection. The market is also expanding with specialized equipment like filtration systems, membrane filtration, and centrifugal separators for effective separation and purification of egg components.

Shift Toward Plant-Based Processing Equipment: By 2028, we may see specialized machines tailored exclusively for plant-based egg analogues, responding to veganism’s growth.

Integration of AI-driven Inventory Optimization: Smart systems will predict demand spikes and optimize raw material usage, drastically cutting waste.

Expansion of Enzyme Modification Technologies: This will allow manufacturers to customize egg product functionality for specific health and culinary needs.

Innovator Spotlight: Moba Group B.V. is pioneering AI-integrated robotic systems that optimize production flow and reduce contamination risks, setting a new industry standard.

Are we ready to redefine the egg processing industry around these bold moves, or will traditional methods hold back progress?

Prioritize AI-driven inventory optimization for liquid and dried egg segments to minimize waste and increase responsiveness.

Invest in shockwave and enzyme modification technologies to boost energy efficiency and product quality.

Develop partnerships focusing on plant-based egg alternative processing to capture emerging consumer demographics.

Implement advanced automation systems including robotics for biosecurity and operational speed.

Adopt sustainable sourcing protocols and cage-free system insurance schemes aligning with consumer ethics.

Leverage big data and system integration to enhance shelf life and functional properties of egg products.

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

In-depth research highlights innovation in egg powder production and drying technologies, including spray drying equipment, freeze-drying systems, and dehydration units that maintain nutritional value and extend shelf life. The use of homogenization equipment and mixing tanks improves consistency in egg blending machines, while ultrafiltration units and egg centrifuge systems optimize separation processes for egg whites and yolks. Advanced egg quality analyzers and egg inspection systems ensure product standards, complemented by egg shell removers and egg handling robots that increase operational efficiency and reduce contamination risks. The market also focuses on sustainable packaging innovations with egg packaging equipment designed for safety and convenience. Overall, these technologies contribute to higher throughput, improved egg processing quality, and better compliance with food safety regulations.

The Egg Processing Equipment Market is transitioning from a traditional manufacturing model to a future-oriented ecosystem driven by technology, sustainability, and shifting consumer values. From combating contamination risks with robotics to innovating plant-based alternatives and applying shockwave technology, the market is transforming its DNA. The question for industry leaders is no longer if they should innovate, but how boldly.

Safe and Secure SSL Encrypted