"Gearbox health is no longer a maintenance issue—it's a competitive differentiator." – Senior Analyst, Global Wind Energy Council (2024)

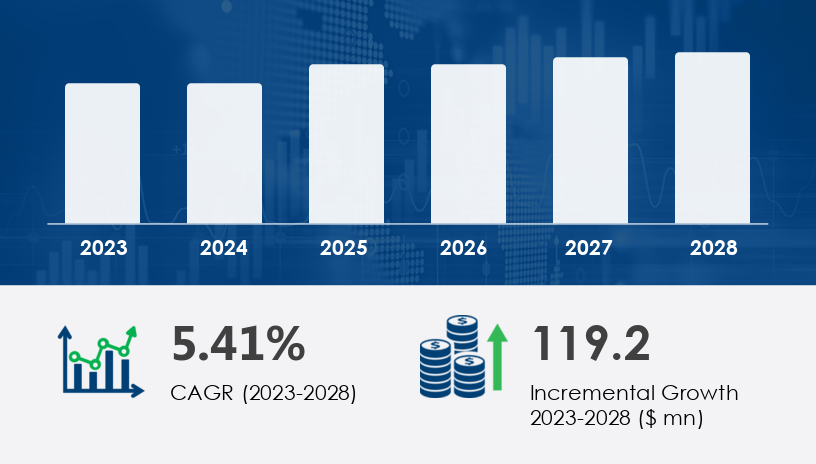

The wind turbine gear oil market is entering a next-gen phase of reinvention. Once considered a maintenance necessity, gear oil has become a strategic asset as turbine performance, uptime, and sustainability take center stage. From 2024 to 2028, this market is forecast to grow by USD 119.2 million, expanding at a CAGR of 5.41%, propelled by a surge in wind energy capacity and a growing preference for synthetic and biodegradable lubricants.

While innovations like gearless turbines threaten to reduce reliance on gear oils, the sector is responding with smarter oils, predictive maintenance, and bio-based formulations that cater to regulatory and operational needs. The result? A market in flux, but rich with opportunity.

For more details about the industry, get the PDF sample report for free

From 2019 to 2023, the wind turbine gear oil market expanded in lockstep with the global wind energy boom. As gearbox design complexity grew, so too did the need for high-performance oils. Now, with digital wind farms and sustainability policies gaining traction, 2024–2028 marks a pivot toward precision-engineered lubricants and lifecycle management.

Legacy Disruption: Mineral oils dominated due to low cost but underperformed in harsh climates.

New Strategy Emerging: Synthetic oils are now essential for cold climates, thermal stability, and extended turbine life.

Analyst Insight: “Synthetic oils not only extend service intervals but reduce carbon footprint—aligning with both OEM specs and ESG mandates.”

Business Case: In 2024, a Chinese wind farm upgraded from mineral to synthetic oils across 100 turbines, reducing downtime by 18% and extending service intervals by 30%.

Stats:

Synthetic gear oil segment was valued at USD 264.80 million in 2018.

Forecasted to witness significant growth from 2024 to 2028.

Legacy Disruption: Offshore turbines suffered from lubrication failures due to salt, pressure, and cold temperatures.

New Strategy Emerging: Adoption of extreme-pressure synthetic oils and predictive oil analytics.

Business Case: A North Sea wind farm integrated condition monitoring and saw gearbox lifespan increase by 22%.

Stats:

Offshore turbines demand low pour point and oxidation-stable oils.

Regular oil analysis minimizes unplanned downtime, which gearboxes cause up to one-third of.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report

Legacy Disruption: Larger turbines stressed traditional oil specs beyond safe limits.

New Strategy Emerging: Formulations with high viscosity index, anti-wear additives, and thermal stability now meet next-gen turbine demands.

Analyst Insight: “Gear oil for 5+ MW turbines must now function more like a smart component—predictive, durable, and sustainable.”

Business Case: Siemens Gamesa’s new 6.5 MW platform mandates use of low-carbon synthetic gear oils to meet EU biodegradability mandates.

Stats:

High-capacity turbines drive demand for predictive maintenance tools.

EU to mandate biodegradable gear oils in new farms by 2030.

Sustainability Mandates

With new EU regulations requiring biodegradable gear oils by 2030, companies like Shell, investing USD 150 million in renewable lubricants, are positioning themselves as ESG leaders.

Digitalization & Predictive Maintenance

GE’s Digital Wind Farm platform is setting benchmarks in lubricant lifecycle monitoring. Oils are now judged not only by their chemical profile but by their ability to integrate into IoT-based maintenance ecosystems.

OEM-Driven Product Design

New gearbox designs and proprietary performance standards are pushing oil companies to collaborate with turbine OEMs like Schaeffler, who recently partnered with Siemens Gamesa to co-develop optimized gear systems.

The Wind Turbine Gear Oil Market is growing steadily in response to rising global investments in renewable energy, particularly wind power. Essential to wind turbine functionality, wind turbine lubricant plays a crucial role in gearbox maintenance, directly impacting wind turbine performance and wind turbine reliability. Both synthetic lubricant and mineral gear oil types are used depending on application needs, with onshore wind lubrication and offshore wind application driving different product demands. The increasing adoption of digital wind farm infrastructure has also improved operational tracking, boosting wind farm efficiency and turbine efficiency boost. Attributes such as thermal resistance, oxidation stability, low-temperature properties, and evaporation loss are key factors in selecting high-performance turbine gearbox oil. As wind farm operators aim for cost-effective performance, lubricant durability, high load capacity, and gear oil longevity are becoming essential for efficient and reliable turbine operation.

Bio-Based Dominance: By 2028, over 30% of gear oils used in wind turbines could be bio-based, meeting stringent lifecycle emissions targets.

AI-Based Lubrication Scheduling: AI platforms will dynamically adjust oil change intervals, reducing waste and cost.

Gearless Revolution Containment: While gearless turbines gain ground, hybrid systems may create niche opportunities for high-load synthetic oils.

Innovation Example: Wärtsilä’s 2024 launch of a next-gen gear oil targeting 20% longer service life and predictive maintenance integration.

As oil becomes a digital asset, is your product ready for real-time performance validation?

Prioritize Bio-Based Innovation

Adopt bio-based gear oil R&D to comply with emerging regulations and appeal to ESG-conscious investors.

Integrate AI-Driven Oil Analytics

Deploy AI-driven inventory optimization and predictive analytics across turbine networks.

Expand OEM Co-Development

Collaborate with turbine manufacturers to meet evolving OEM lubricant specifications and gain early product approvals.

Enhance Low-Temperature Performance

Focus on cold-weather oils with advanced anti-wear and antioxidant additives for offshore applications.

Prepare for Lifecycle Cost Audits

With sustainability under scrutiny, establish lubricant recycling programs and lifecycle transparency.

Deploy Digital Wind Farm Support

Ensure gear oils are compatible with smart turbine platforms for digital integration.

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

Research in the Wind Turbine Gear Oil Market focuses on developing advanced gear oil formulations that support turbine operation optimization and operate efficiently under varied environmental conditions. Innovations emphasize base oil synthetic blends and gear oil additives that improve lubricant thermal property, enhance gear oil stability, and meet demands for lubricant compatibility with different wind turbine components. The role of industrial lubricants in renewable energy lubricant applications is increasingly important, with efforts to improve oil lubrication systems and implement gearbox optimization for consistent energy output increase. Technologies like digital twin technology and gearbox damage detection are transforming maintenance strategies, contributing to maintenance cost reduction and extending operational life. As wind turbine innovation accelerates, research into harsh condition lubricants and their impact on wind energy components is crucial to sustaining long-term growth and reliability across wind power systems.

The wind turbine gear oil market is no longer about lubrication—it's about unlocking operational efficiency, enabling sustainability, and safeguarding billion-dollar wind assets. With synthetic oils, AI-driven monitoring, and bio-based compliance, the next era is redefining what performance means.

Are we thinking big enough about oil as an intelligent asset in the renewable energy revolution?

Safe and Secure SSL Encrypted