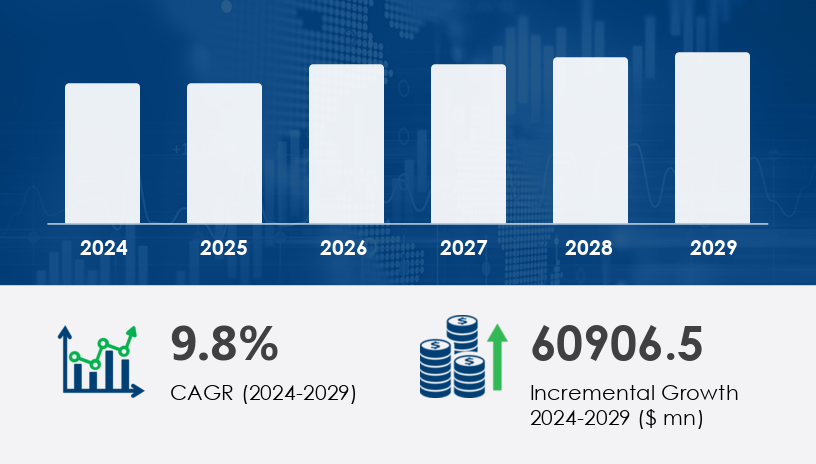

2025 Outlook: The MRO automation solutions market is poised to expand by USD 60.91 billion, achieving a compound annual growth rate (CAGR) of 9.8% between 2024 and 2029. This expansion is driven by the increasing adoption of automation technologies across various industries. In an era where operational efficiency and equipment reliability are paramount, the Maintenance Repair Operations (MRO) market for automation solutions stands at the forefront of industrial transformation.

For more details about the industry, get the PDF sample report for free

A primary driver of this growth is the rising trend of outsourcing maintenance operations. Both process and discrete industries are increasingly opting for third-party service providers to manage their maintenance and operational needs. This shift is primarily due to the high costs associated with maintaining an in-house workforce and the extensive product knowledge and training required. Consequently, end-users are seeking comprehensive solutions from singular providers to manage their complete automation solution's maintenance and repair requirements.

Emerging trends in the MRO market include the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning. These technologies enable predictive maintenance, real-time monitoring, and data-driven decision-making, leading to enhanced operational efficiency and reduced downtime. Industries such as energy and power, water and wastewater, oil and gas, and manufacturing are at the forefront of adopting these innovations to optimize their MRO practices.

The Maintenance Repair Operations (MRO) Market is rapidly evolving due to the integration of predictive maintenance and IoT sensors, which enable more efficient and proactive asset management. Automation solutions such as industrial robots and maintenance software streamline repair processes while improving energy efficiency across various sectors including power generation, oil and gas, and water management. Key components like pumps, motors, gearing, spare parts, fasteners, and lubricants remain essential for maintaining industrial equipment performance. The growing emphasis on green facilities and sustainable buildings pushes the market toward reducing the carbon footprint, while ensuring compliance with safety standards through advanced safety equipment and repair tools.

The MRO market is segmented based on various criteria:

End-user: Process industries, Discrete industries

Type: MRO items, Services

Application: Preventive maintenance, Predictive maintenance, Corrective maintenance

Channel: OEMs, Third-party service providers, Distributors

The process industries segment is estimated to witness significant growth during the forecast period. This sector encompasses industries such as energy and power, water and wastewater, and oil and gas, all of which require high levels of equipment reliability and uptime. The global power industry is experiencing growth due to increasing electricity demand, urbanization, and infrastructure upgrades. Renewable energy sources are gaining popularity, contributing to the market's evolution. The integration of automation solutions in these industries is essential for minimizing downtime and promoting sustainability through green MRO practices .

The MRO market exhibits varied growth across different regions:

North America

Europe

APAC

South America

Middle East and Africa

The Asia Pacific (APAC) region is projected to experience substantial expansion during the forecast period, contributing 56% to the global market growth. Key drivers include the region's industrialization, increasing automation demands, and substantial investments in power, water and wastewater treatment, and process industries. Government initiatives, rising living standards, a strong industrial base, and expanding automotive manufacturing sectors further fuel the market growth. Additionally, the adoption of green energy production, digitization, and smart technologies in the power industry, as well as the implementation of green MRO practices, are significant trends shaping the market in APAC.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report.

A significant challenge facing the MRO market is the shortage of skilled labor. The increasing complexity of automation technologies necessitates a highly skilled workforce capable of managing advanced systems. However, the global shortage of qualified personnel poses a barrier to the effective implementation and maintenance of these technologies. This skill gap can lead to operational inefficiencies and increased downtime, impacting the overall performance of MRO operations.

Market research highlights the increasing adoption of smart technologies and digital transformation in MRO operations. The use of cloud platforms and data analytics enhances remote monitoring and real-time monitoring capabilities, allowing for better decision-making and operational efficiency. Industries rely heavily on smart inventory management systems, incorporating barcode scanners, industrial vending, and biometric access to optimize the availability of critical electrical components, semiconductor chips, and automotive parts. Just-in-time delivery models and process optimization help reduce operating expenses and improve responsiveness, particularly in sectors like HVAC systems and data centers where uptime is crucial.

In-depth analysis reveals a growing demand for integrated asset management and comprehensive maintenance services that leverage automation and connectivity to minimize downtime. The synergy between IoT sensors, predictive maintenance, and maintenance software facilitates a shift from reactive to proactive repairs, enhancing equipment lifespan and reducing costs. As MRO activities expand in the energy sector and other heavy industries, the focus on sustainable buildings and green facilities becomes a strategic priority. Overall, the market is driven by the need for automation solutions, smart inventory controls, and cloud platform capabilities that support continuous improvement and operational excellence in maintenance repair operations.

Companies in the MRO sector are adopting various strategies to enhance their competitive edge:

Strategic Alliances and Partnerships: Collaborations with technology providers to integrate advanced solutions into MRO operations.

Geographical Expansion: Establishing a presence in emerging markets to tap into new customer bases.

Product and Service Innovation: Developing new MRO products and services to meet the evolving needs of industries.

Digital Transformation: Investing in digital platforms and tools to streamline MRO processes and improve efficiency.

These strategies aim to address the challenges posed by the skilled labor shortage and the increasing demand for advanced MRO solutions. By leveraging technology and expanding their reach, companies can enhance their service offerings and maintain a competitive advantage in the evolving MRO market.

1. Executive Summary

2. Market Landscape

3. Market Sizing

4. Historic Market Size

5. Five Forces Analysis

6. Market Segmentation

6.1 End-user

6.1.1 Process industries

6.1.2 Discrete industries

6.2 Type

6.2.1 MRO items

6.2.2 Services

6.3 Application

6.3.1 Preventive maintenance

6.3.2 Predictive maintenance

6.3.3 Corrective maintenance

6.4 Channel

6.4.1 OEMs

6.4.2 Third-party service providers

6.4.3 Distributors

6.5 Geography

6.5.1 North America

6.5.2 APAC

6.5.3 Europe

6.5.4 South America

6.5.5 Middle East And Africa

7. Customer Landscape

8. Geographic Landscape

9. Drivers, Challenges, and Trends

10. Company Landscape

11. Company Analysis

12. Appendix

Safe and Secure SSL Encrypted