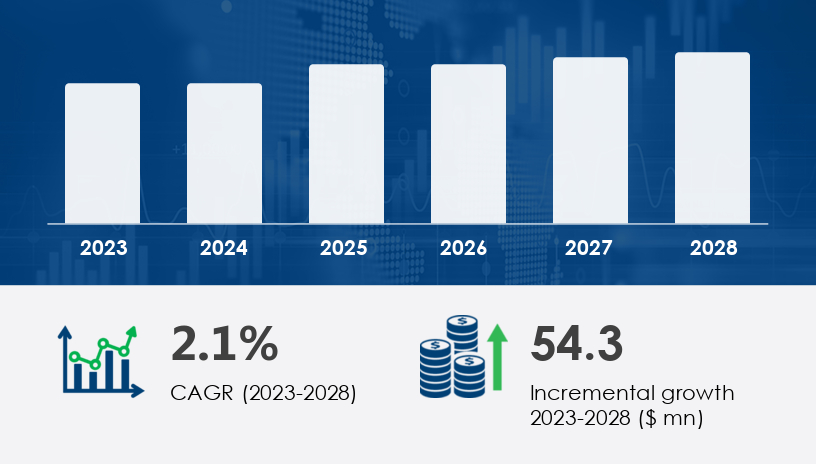

The Methyl Isobutyl Carbinol (MIBC) market is poised for a notable expansion, expected to increase by USD 54.3 billion between 2023 and 2028 at a steady CAGR of 2.1%. This growth is largely underpinned by the compound’s critical role in mineral flotation, surface coatings, and the booming construction industry, particularly in Asia-Pacific and South America. In this comprehensive guide, we provide strategic insights, trend analysis, and expert commentary on the evolving dynamics of the MIBC market — a cornerstone of several industrial applications that’s both foundational and future-facing.

For more details about the industry, get the PDF sample report for free

Methyl Isobutyl Carbinol is a stable, colorless, flammable organic compound with the chemical formula C6H14O. It serves multiple industrial roles including:

Frother in mineral flotation processes

Lubricant oil additive

Solvent in greases and resins

Component in surface coatings and brake fluids

Its standout property? MIBC creates stable froths that enhance mineral separation and improve recovery rates — a critical function in the global mining sector.

The Methyl Isobutyl Carbinol (MIBC) Market is primarily driven by its critical role as a chemical frother in the froth flotation and mineral flotation processes, which are essential for separating hydrophobic minerals from hydrophilic waste in the mining sector. This organic compound is widely used in the extraction of copper ores and molybdenum ores, enabling high yield and effective metal recovery. MIBC's solvent properties and fast kinetics contribute to selectivity efficiency and the formation of dry froths, optimizing the flotation process. Beyond mining, the compound also sees application as a lubricant additive, grease additive, and in biocide applications and as a corrosion inhibitor within the construction industry. The demand for specialty chemicals in adhesives, sealants use, and surface coatings is also contributing to MIBC’s growth, particularly due to its role in enhancing product performance and offering a non-toxic alternative in sustainable construction.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report.

With the global construction industry projected to expand by 70% by 2030, demand for MIBC-based surface coatings and paints is accelerating. Its use in high-performance coatings provides not only aesthetic finish but also corrosion resistance and chemical stability.

MIBC’s fast kinetics and excellent selectivity make it an ideal frothing agent in the flotation process — separating valuable minerals like copper and iron from waste material.

Real-world example: In a South American copper mine, switching to MIBC-based frothing increased metal recovery by 18%, while reducing chemical consumption by 12%.

The additive properties of MIBC improve the performance of lubricants and brake fluids — key in advanced automotive manufacturing, especially with the rise of electric vehicles demanding higher thermal tolerance in fluids.

Building and Construction

MIBC demand is surging in paints, coatings, and adhesives. This segment, valued at USD 150.1 million in 2018, continues to expand in line with infrastructure growth.

Mining

Integral to mineral recovery in froth flotation — particularly in APAC due to vast mineral reserves.

Automotive & Aerospace

Used in anti-wear agents, resins, and surface coatings for high-performance applications.

The global market is segmented into the following regions:

Asia-Pacific is expected to contribute 53% of global MIBC market growth. The reasons are clear:

Massive mining operations in China, India, and Australia.

Rapid infrastructure growth demanding advanced coatings.

Growing automotive production hubs.

Froth flotation remains the dominant application, especially in mining-heavy geographies.

Demand for eco-friendly coatings is set to reshape MIBC usage in construction and automotive.

Regulatory pressures are mounting, necessitating greener alternatives and safer disposal methods.

With regulatory scrutiny tightening due to MIBC’s flammable and toxic nature, the push for greener, biodegradable frothers is gaining momentum. Companies that pivot early to safe substitutes will gain competitive advantage.

High-solids coatings and rubber antioxidants are creating new growth avenues, particularly in EV manufacturing and aerospace, where MIBC’s durability-enhancing properties shine.

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

Health Risks: MIBC exposure can cause headaches, dizziness, and chronic symptoms with prolonged contact.

Compliance Costs: Stricter environmental regulations may increase production and disposal costs for MIBC producers.

Emerging biosolvents and synthetic frothers may displace traditional MIBC in low-risk applications.

| Pros | Cons |

|---|---|

| High frothing efficiency | Flammable and toxic |

| Versatile industrial applications | Environmental disposal challenges |

| Enhances lubricant and brake fluid performance | Regulatory scrutiny in EU and North America |

Invest in R&D for safer, high-efficiency MIBC alternatives to meet regulatory and environmental demands.

Strengthen presence in APAC, especially for companies targeting mining and construction sectors.

Explore strategic alliances with automotive OEMs and coating manufacturers to diversify application streams.

Get more details by ordering the complete report

Facing regulatory headwinds in Europe, BASF reallocated MIBC production capacity to South Korea, aligning with booming mining demand in Southeast Asia. The result? A 23% uptick in regional sales and stronger long-term contracts with copper mining companies.

Research analysis of the MIBC Market reveals its rising adoption in eco-conscious industries seeking eco-friendly practices and biodegradable options, particularly in water-based paints and paint formulations. MIBC’s value as an industrial solvent in coating enhancement is increasingly recognized, especially in segments that demand superior chemical stability and long-lasting finishes. In mineral processing, MIBC supports efficient ore separation and process optimization, while its additive efficiency adds functional benefits across applications. The compound’s movement through supply chains typically involves bulk rail, tank trucks, and ISO containers, ensuring flexible logistics. Moreover, MIBC’s contribution to sustainable construction and industrial solvent innovations reflects its growing relevance across diverse markets. As industries push for green chemistry and performance-driven solutions, MIBC remains integral to balancing functionality with environmental responsibility.

While MIBC remains irreplaceable in many mineral and coating processes, the future points toward hybrid frothers, low-VOC coatings, and closed-loop recycling systems. Players that lead on innovation and sustainability will define the next phase of market leadership.

Despite its regulatory challenges, Methyl Isobutyl Carbinol is far from obsolete. Its multifunctional profile, strong demand base, and industrial indispensability ensure that MIBC will remain a core chemical — especially in regions where mining and infrastructure growth are surging.

Safe and Secure SSL Encrypted