A surprising shift is redefining the polymer landscape. Once relegated to niche packaging and adhesives, the ethylene acrylic acid copolymer market is now powering the next generation of high-performance, eco-conscious materials. As BASF ramps up capacity and LG Chem launches massive production facilities, the message is clear: this market is not just growing—it’s accelerating. In a world demanding both functionality and sustainability, we are witnessing a Market Redefined, driven by green chemistry, 3D printing, and a fierce appetite for advanced barrier solutions.

For more details about the industry, get the PDF sample report for free

Legacy Disruption: Traditional synthetic adhesives struggle with sustainability and substrate versatility.

New Strategy Emerging: EAA adhesives are gaining momentum for their thermal stability, chemical resistance, and performance on multiple substrates.

Analyst Insight: The packaging boom, amplified by e-commerce, is “catalyzing a shift toward flexible, high-bond EAA solutions.”

Business Case: A Japanese consumer electronics firm adopted EAA-based adhesives for moisture-resistant device packaging—reducing failure rates by 35%.

Stats: Adhesives valued at USD 146 million in 2019; packaging sector continues to drive segment expansion through 2029.

Legacy Disruption: PE and LDPE films lag in moisture and gas barrier efficiency.

New Strategy Emerging: EAA copolymers are now chosen for acid-food applications and high-speed packaging lines requiring excellent seal strength.

Analyst Insight: “Barrier innovation is where EAA moves from additive to core material,” says a Technavio materials analyst.

Business Case: A food-packaging startup in India shifted to EAA barrier layers for extended shelf life—gaining shelf-life extension of 20% and shelf-space in major retailers.

Stats: EAA copolymers offer heat sealability, resistance to grease, solvents, and water; growing demand in APAC food packaging fuels coating innovation.

Legacy Disruption: PVC-based components face regulatory pressure and aesthetic limitations.

New Strategy Emerging: EAA’s scratch resistance, color matching, and UV stability meet consumer demand for durable, eco-conscious alternatives.

Analyst Insight: “From flooring to 3D-printed parts, EAA blends are now a form-meets-function champion,” notes a DuPont innovation lead.

Business Case: A European home goods brand switched to EAA polymer blends for stain-resistant, recyclable cookware coatings—boosting product returns by 18%.

Stats: EAA finds strong uptake in paints, coatings, textiles, and personal care packaging.

1. Scale Meets Innovation

Major producers like BASF, LG Chem, and Dow are not just expanding capacity—they’re rethinking formulations. BASF’s €100M investment in Ludwigshafen boosts output by 50,000 metric tons annually.

2. Green Chemistry Adoption

With the rise of bio-based acrylic acid, firms prioritizing circular economy principles are setting the pace. New production processes such as melt crystallization and emulsion polymerization are replacing energy-intensive methods.

3. Application Diversification

EAA is expanding into 3D printing, injection molding, and electrical components. SABIC’s 2025 launch of TARCENE EAA signals a new chapter in high-impact, multi-application polymers.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report.

AI-enabled EAA customization—Dynamic EAA blends adapted in real-time for end-use needs via AI-led polymer design platforms.

Recyclable EAA packaging loops—Bio-based EAA integrated into zero-waste packaging ecosystems for food and pharma.

EAA as a core material in EVs—From sealing to interior finishing, lightweight, flame-retardant EAA enters electric vehicle design pipelines.

Company Example: Dow and INEOS’ 2024 collaboration focuses on developing novel EAA solutions for automotive and construction, aiming for market-ready applications by 2026.

If EAA can outperform and outlast—why isn’t it replacing more legacy materials now?

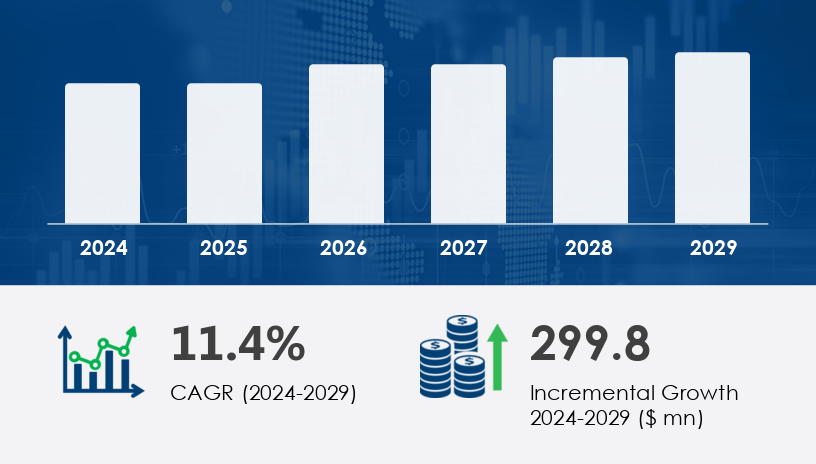

The Ethylene Acrylic Acid (EAA) Copolymer Market is experiencing steady growth, driven by increased consumer demand for eco-friendly materials and sustainable solutions in sectors such as food packaging, flexible packaging, and e-commerce packaging. Composed primarily of acrylic acid and ethylene monomer, these polymer resins offer exceptional adhesive strength, barrier properties, and chemical resistance, making them ideal for packaging films and industrial adhesives. With heightened awareness of environmental impact and rising health concerns, there’s growing preference for bio-based copolymers derived from renewable feedstocks, as opposed to conventional petroleum derivatives sourced from crude oil. The market is further supported by lifestyle changes, rising focus on product pricing, and the need for heat sealing solutions with superior thermal stability. Despite challenges related to raw materials and supply chain constraints, EAA copolymers remain essential in coating applications and specialty chemicals.

To seize the EAA opportunity from 2025 to 2029, market leaders must act with urgency and insight:

Optimize Global Supply Chains

Use AI-driven inventory optimization for packaging polymers to mitigate raw material volatility.

Invest in Bio-Based Transitions

Leverage green chemistry in EAA resin manufacturing to future-proof product lines.

Integrate with Emerging Technologies

Support 3D printing applications of EAA copolymers for custom manufacturing at scale.

Focus on Application Expansion

Build cross-functional R&D to enable UV-stable, moisture-resistant EAA in electronics and automotive.

Embed Sustainability Metrics

Apply life cycle analysis for polymer blends to align with evolving ESG regulations.

Master Performance Testing

Use advanced tools like gel permeation chromatography (GPC) and FTIR spectroscopy for polymer quality assurance.

Get more details by ordering the complete report

Research in the Ethylene Acrylic Acid Copolymer Market is centered around copolymer innovation and adapting to regulatory challenges while improving adhesion properties on polar substrates. Advances in technological advancements are enabling the development of high-performance resins for diverse end-use applications including construction materials and automotive components. Scientists are exploring enhanced moisture barrier capabilities and using processes like melt crystallization, liquid-liquid extraction, and biotransformation to refine polymer quality and sustainability. The use of EAA copolymers in adhesive and coating sectors is increasing due to their compatibility with specialty chemicals and demand for performance in aggressive environments. However, the market continues to be influenced by market dynamics, shifting production costs, and growing concerns about the long-term viability of fossil-based options. These insights are guiding future material strategies focused on balancing functionality with environmental responsibility.

The ethylene acrylic acid copolymer market is not evolving—it’s transforming. What was once a materials category focused on packaging is now a central pillar in sustainable product innovation, advanced manufacturing, and cross-sector performance improvement.

By 2029, EAA will be embedded in every conversation about next-generation materials—from additive manufacturing to zero-waste packaging to smart construction.

Are we thinking big enough about what polymers can do in the next industrial era?

Access our Full 2025–2029 Playbook to lead your market transformation.

Safe and Secure SSL Encrypted