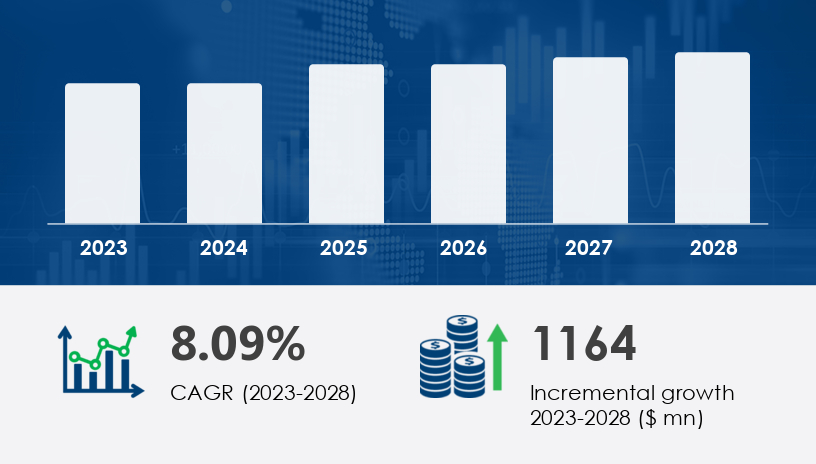

The diamond coatings market is poised for a significant leap, with forecasts projecting a $1.16 billion surge by 2028 at a robust CAGR of 8.09%. As enterprise IT demands evolve and the global data landscape expands exponentially, the need for high-performance, durable, and power-efficient material solutions—like diamond coatings—has never been greater.

In this 2025 Outlook and Comprehensive Guide, we delve into the driving forces, regional dynamics, end-user trends, and innovation shaping the diamond coatings industry. This analysis serves as a strategic roadmap for manufacturers, investors, IT leaders, and innovation-driven enterprises aiming to capitalize on a rapidly evolving, high-value materials sector.

For more details about the industry, get the PDF sample report for free

Diamond coatings are ultra-thin layers of synthetic diamond applied to surfaces using techniques such as chemical vapor deposition (CVD) or physical vapor deposition (PVD). Known for their exceptional hardness, thermal conductivity, and chemical resistance, these coatings are transforming industries ranging from IT infrastructure to aerospace, electronics, and healthcare.

The Diamond Coatings Market is growing steadily due to increasing demand in sectors requiring extreme wear resistance, thermal conductivity, and hardness property. Technologies such as CVD coating and PVD coating are commonly used to apply diamond films onto various substrate materials, enhancing surface durability and enabling superior coating adhesion. Diamond coatings are extensively used in cutting tools, heat sinks, and semiconductor substrates where thermal management and low friction are critical. Applications extend into medical implants and prosthetic coatings, where biomedical applications benefit from chemical stability and corrosion resistance. The coatings also improve optical transparency, making them ideal for optical windows, while providing anti-scratch surfaces in electronic devices and high-precision mechanical components. These performance advantages support the adoption of diamond coatings in both industrial and consumer applications.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report.

Diamond coatings offer a cost-competitive alternative to natural diamonds, while maintaining comparable durability, especially for cutting tools and heat-sensitive electronic components. This makes them ideal for industries navigating economic pressures and digital transformation.

With unstructured data from IoT devices, virtual servers, and financial systems flooding enterprise systems, storage infrastructure must now deliver speed, durability, and efficiency. Diamond-coated components in HDDs, SSDs, AFAs, and NVMe-based solutions help enterprises meet these demands by:

Reducing power consumption

Enhancing thermal management

Improving response times

This is especially critical for mega data centers and hybrid cloud platforms, which are scaling rapidly across verticals like finance, healthcare, and e-commerce.

Europe is expected to contribute 38% of global market growth.

Strong uptake in automotive, microelectronics, aerospace, and telecommunications sectors.

High-tech advances like 5G, VR/AR, smart manufacturing, and 4K/8K video are propelling demand for diamond-coated components.

Accounted for $474.9 million in 2018

Fueled by NVMe adoption, data analytics platforms, and real-time computing

Applications: Heat sinks, optical windows, electrical isolators, high-performance computing

Usage in prosthetics, surgical tools, and wear-resistant equipment

Medical-grade diamond coatings provide biocompatibility and corrosion resistance

Demand growing in automotive engineering, construction equipment, and high-precision tools

From IIT Madras' innovations in heat-dissipating diamond layers to ongoing breakthroughs in nano-coating tech, research and development is a core growth engine.

Emerging sectors include:

Oil & gas exploration

Aerospace-grade optics

AI-integrated manufacturing systems

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

High wear resistance & durability

Superior thermal conductivity

Lightweight and corrosion-resistant

Cost-effective vs. industrial diamonds

High initial processing costs

Competition from substitutes like TiN, CrN

Limited suppliers and skilled labor pool

Alternatives like titanium nitride, zirconium nitride, and chromium carbide are eating into market share by offering similar performance with more widespread adoption.

Supply chain bottlenecks and fluctuating raw material costs could hinder expansion, particularly in semiconductors and aerospace.

As data privacy laws tighten globally, storage solutions must be both technically robust and regulation-ready—a challenge for enterprises still adapting legacy systems.

Get more details by ordering the complete report

The next 3–5 years will likely see:

Broader adoption in AR/VR, 6G-ready devices, and quantum computing components

A sharp rise in AI-optimized storage using diamond-coated flash arrays

Market consolidation as major players like Element Six, Oerlikon, and Pure Storage double down on proprietary diamond solutions

Invest in Hybrid Cloud Readiness – Deploy diamond-coated storage for scalable, energy-efficient infrastructure.

Partner with Specialized Coaters – Collaborate with leaders like Acree Technologies and NeoCoat SA for customized solutions.

Focus on Edge Applications – Target sectors like telehealth, smart cities, and autonomous vehicles for high-growth opportunities.

Mitigate Risks – Diversify supplier base to counter substitute material pressure.

Ongoing innovation in the diamond coatings market is being driven by advances in materials science and deposition techniques. The development of nanocrystalline diamond and polycrystalline diamond layers enables improved surface finish, abrasion resistance, and extended tool life in demanding environments. Precision applications, such as precision machining and industrial tools, benefit from engineered coating thickness and optimized diamond layers that provide friction reduction and erosion resistance. Emerging uses in high-performance computers leverage diamond’s superior electrical insulation and thermal conductivity for enhanced device performance. The use of vacuum chambers and high-pressure deposition methods ensures consistency and quality in thin film production. Moreover, diamond coatings contribute to creating non-stick surfaces and boosting wear protection in high-usage environments, confirming their essential role across industries focused on durability, reliability, and extreme performance.

Safe and Secure SSL Encrypted