Welding Equipment Market Size 2024-2028: Strong Growth Driven by Innovation and Automation

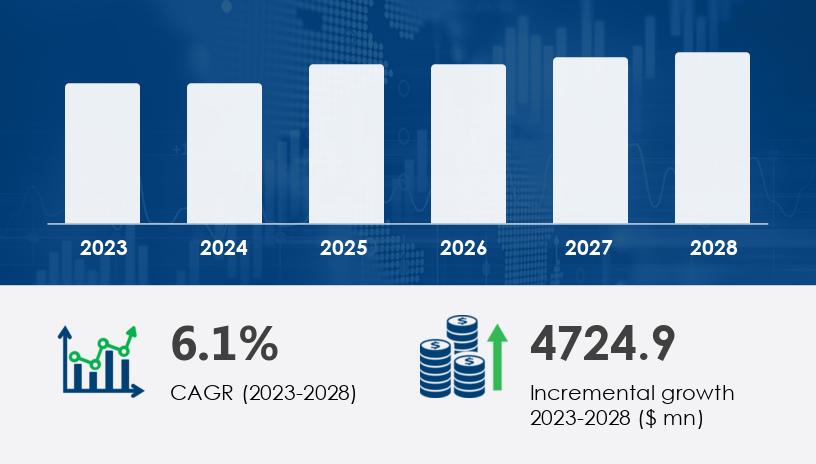

The welding equipment market is forecast to grow by USD 4.72 billion, with a compound annual growth rate (CAGR) of 6.1% between 2023 and 2028. This growth is attributed to key trends such as the rise of advanced welding technologies, particularly friction stir welding (FSW), and the increasing adoption of automated welding solutions across various industries, including automotive, construction, and aerospace.

For more details about the industry, get the PDF sample report for free

Market Segmentation

The welding equipment market is segmented based on end-user industries and geographic regions, with a focus on both industrial-scale and DIY applications.

-

End-user Segments:

- Automotive: Significant growth is expected in the automotive sector, driven by stringent quality requirements and the adoption of advanced welding technologies such as robotic welding. This segment was valued at USD 3.29 billion in 2018 and is projected to continue expanding.

- Construction

- Aerospace and Defense

- Shipbuilding

- Others

-

Geographic Segments:

- APAC:

- North America:

- Europe:

- South America

- Middle East and Africa

Market Dynamics: Drivers, Trends, and Challenges

-

Key Drivers:

- Emergence of Friction Stir Welding (FSW): FSW technology is gaining traction in the automotive sector due to its ability to join base metals without filler rods or excessive heat generation. This innovative process is crucial for producing lightweight, defect-free components, especially in the automotive and aerospace sectors.

- Increasing Demand for Electric Current-powered Welding Processes: Electric current plays a vital role in the welding process, helping melt base metals for efficient joining. This is especially important in industries requiring high-quality, durable welds.

-

Key Trends:

- Automated Welding Solutions: The adoption of automated welding solutions has surged, with robots becoming integral to welding processes. These systems improve productivity, reduce the need for skilled labor, and enhance precision, especially in automotive manufacturing.

- Advanced Welding Techniques: Techniques like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, which offer speed and precision, are becoming more popular due to their ability to handle difficult materials like aluminum, magnesium, and stainless steel.

Get more details by ordering the complete report

-

Key Challenges:

- Lack of Skilled Workforce: A shortage of skilled welders, especially in countries like the US, India, and China, poses a challenge for the market. As many experienced welders near retirement, the industry faces a gap in skilled labor. Additionally, the complexity of certain welding systems, such as gas supply and equipment operation, can deter newcomers.

Key Players in the Market

Several key players are driving innovation in the welding equipment market, including:

- Ador Welding Ltd.

- Amada Co. Ltd.

- Banner Welding Inc.

- Carl Cloos Schweisstechnik GmbH

- Daihen Corp.

- Doncasters Group Ltd.

- Enovis Corp.

- Fronius International GmbH

- Illinois Tool Works Inc.

- Kobe Steel Ltd.

- Kriton Weld Equipments Pvt. Ltd.

- Miller Electric Manufacturing Co.

- Mitco Weld Products Pvt. Ltd.

- Mogora Pvt. Ltd.

- OBARA Group Inc.

- Panasonic Holdings Corp.

- Sonics and Materials Inc.

- Telwin Spa

- The Lincoln Electric Co.

- voestalpine AG

Future Market Insights

The welding equipment market is expected to continue its steady growth, driven by technological advancements in welding processes, increasing demand for automation, and the need for high-quality welding solutions in various industries. However, addressing the skilled labor shortage remains crucial for sustaining this growth. As manufacturers continue to develop more efficient and user-friendly welding solutions, the market will likely see more widespread adoption across both industrial and consumer applications.