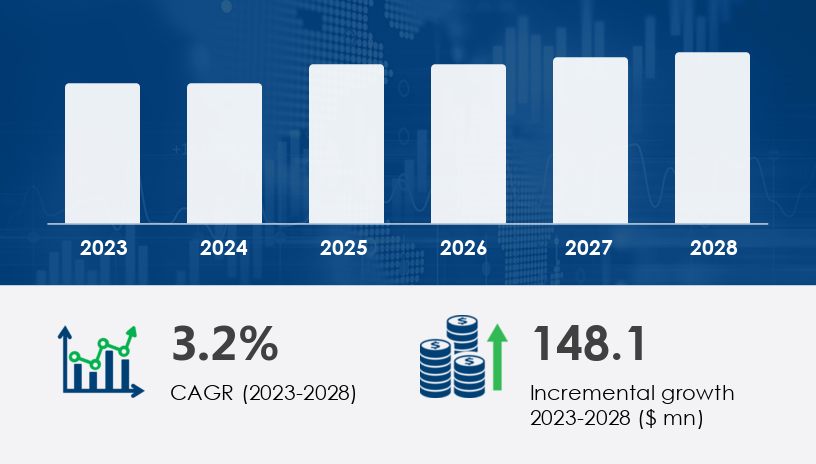

The global slip rings market is poised for steady growth between 2024 and 2028, with a projected increase of USD 148.10 million at a CAGR of 3.2%. This growth is powered by evolving design innovations, increasing demand for high-voltage applications such as wind energy generation, and expanding use in commercial sectors, including motors, escalators, and medical equipment. In this comprehensive guide, we delve into the key market segments—application, type, and region—to provide strategic insights for stakeholders navigating this evolving landscape.

For more details about the industry, get the PDF sample report for free

The slip rings market serves as a critical component in the transmission of power and data between stationary and rotating parts of machinery. As industries continue to evolve, the demand for reliable and efficient slip ring solutions has surged, driven by advancements in technology and the increasing complexity of applications.

| Segment | Key Drivers | Challenges |

|---|---|---|

| Application | Growing industrial automation, renewable energy adoption, medical advancements | High customization costs, integration complexities |

| Type | Demand for high-speed data transmission, miniaturization trends | Design limitations, maintenance requirements |

| Region | Infrastructure development, technological adoption | Regulatory hurdles, market fragmentation |

The commercial application segment leads the market, driven by the increasing availability of technologically advanced slip rings. These are extensively used in motors, generators, and medical devices, particularly in hospitals and shopping malls. The demand for modular variants is also on the rise, enhancing the versatility and efficiency of these components.

Growth Drivers & Challenges: The expansion of commercial infrastructure and the need for reliable power transmission systems are key drivers. However, the high cost of advanced slip ring systems poses a challenge to widespread adoption.

Expert Insight: "The integration of modular slip ring designs is revolutionizing maintenance practices in commercial applications, offering enhanced flexibility and reduced downtime."

Mini Case Study: A leading hospital in Europe upgraded its medical imaging equipment with advanced slip ring systems, resulting in improved operational efficiency and patient throughput.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report

The aerospace and defense sector demands high-performance slip rings capable of operating under extreme conditions. These components are crucial in applications such as radar systems, missile guidance, and satellite communication.

Growth Drivers & Challenges: The increasing defense budgets and advancements in aerospace technologies are driving demand. However, stringent regulatory standards and high development costs present challenges.

Expert Insight: "Innovations in slip ring technology are enabling more compact and durable solutions for aerospace applications, meeting the rigorous demands of the industry."

Mini Case Study: A defense contractor developed a custom slip ring system for a new radar platform, enhancing signal integrity and system reliability.

North America, particularly the U.S. and Canada, leads the slip rings market, driven by advancements in technology and strong demand from sectors like aerospace, defense, and renewable energy.

Growth Drivers & Challenges: High investment in R&D and infrastructure development are key drivers. However, regulatory challenges and market fragmentation pose obstacles.

Expert Insight: "North America's focus on innovation and technological advancement positions it as a leader in the slip rings market."

Mini Case Study: A U.S.-based wind energy company adopted advanced slip ring systems in its turbines, resulting in enhanced performance and reduced maintenance.

Key Fact: North America accounted for a significant share of the market in 2022 and is expected to maintain its leadership through 2032.

The APAC region is experiencing rapid industrialization and urbanization, leading to increased demand for slip rings in various applications, including manufacturing, robotics, and renewable energy.

Growth Drivers & Challenges: Economic growth and infrastructure development are driving demand. However, the need for skilled labor and quality control present challenges.

Expert Insight: "APAC's burgeoning industrial sector is fueling the demand for advanced slip ring solutions, offering significant growth opportunities."

Mini Case Study: A Chinese manufacturing company integrated slip rings into its automated systems, improving efficiency and production capacity.

The Slip Rings Market is experiencing significant growth, driven by expanding applications in sectors such as industrial motors, wind turbines, aerospace systems, and marine propulsion. Key components such as rotary joints, electrical contacts, and conductive rings play vital roles in power transmission and signal transfer across rotating connectors. Advanced designs, including capsule designs, thru bore, pancake style, and miniature circuits, cater to diverse use cases from radar antennas to automation gear. Materials like copper alloys, silver plating, and gold contacts enhance performance by ensuring durability and reliability in low noise and high voltage environments. The integration of shaft mounts, bearing sets, and insulation layers ensures mechanical stability, while swivel joints and energy chains contribute to enhanced operational flexibility in smart manufacturing setups.

Emerging Markets: Expansion into developing regions presents growth opportunities for slip ring manufacturers.

Technological Advancements: Innovations in materials and design can lead to enhanced performance and new applications.

Sustainability Trends: Growing emphasis on renewable energy sources increases demand for slip rings in wind and solar power systems.

Market Fragmentation: The presence of numerous small players can lead to intense competition and pricing pressures.

Regulatory Challenges: Compliance with varying standards across regions can complicate market entry and operations.

Technological Obsolescence: Rapid advancements in technology may render existing slip ring solutions obsolete.

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

Detailed research reveals that modern slip ring assemblies incorporate brush contacts, mercury wetted variants, and fiber optic technologies to meet the demands of advanced systems like robotic arms, test rigs, and video systems. Innovative rotor assemblies and stator units allow seamless integration with torque sensors, optical encoders, and wireless tech, supporting real-time data links and continuous signal integrity. The compatibility with hydraulic seals and pneumatic unions makes them essential in rugged defense equipment and aerospace applications. Furthermore, the use of slip rings in smart sensors and automation systems showcases their adaptability, with design variations improving reliability in environments requiring precise motion and data transfer. These trends underline the growing reliance on slip rings across industries seeking efficient and durable rotating interfaces.

Safe and Secure SSL Encrypted