The sheet metal processing equipment market has undergone significant transformations over the past decade. In 2019, the industry was characterized by traditional manufacturing processes with limited automation. By 2023, advancements in technology, such as the integration of CNC machines and laser cutting systems, had begun to reshape the landscape, leading to increased precision and efficiency.

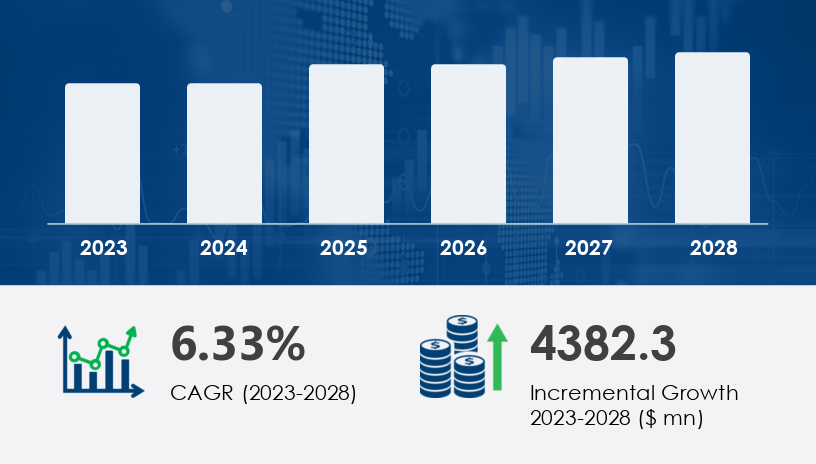

Looking ahead, the forecast for 2024–2028 indicates a continued upward trajectory. The market is projected to grow by USD 4.38 billion with a compound annual growth rate (CAGR) of 6.33%. This growth is driven by several key factors, including the increasing demand for precision metal work, the integration of advanced technologies like AI and IoT, and the expansion of industries such as construction, automotive, and aerospace.

For more details about the industry, get the PDF sample report for free

Legacy Disruption: Traditional cutting methods are being replaced by advanced technologies like laser and plasma cutting, offering higher precision and efficiency.

New Strategy Emerging: Integration of AI and IoT in cutting equipment enables real-time monitoring and predictive maintenance, reducing downtime and improving productivity.

Analyst Insight: The metal cutting segment is estimated to witness significant growth during the forecast period, driven by the increasing demand for high-strength components in various industries.

Business Case: A leading automotive manufacturer implemented AI-powered laser cutting systems, resulting in a 20% reduction in material waste and a 15% increase in production speed.

Legacy Disruption: Manual forming techniques are being supplanted by automated systems that offer consistent quality and reduced labor costs.

New Strategy Emerging: Adoption of robotic arms and CNC-controlled presses enhances the flexibility and scalability of forming processes.

Analyst Insight: Advancements in machinery technology and the rising adoption of robotics in manufacturing processes are influencing the growth of the metal forming segment.

Business Case: An aerospace company integrated robotic forming systems, leading to a 30% increase in production capacity and a 25% reduction in labor costs.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report

Legacy Disruption: Manual welding methods are being replaced by automated welding systems that offer higher precision and repeatability.

New Strategy Emerging: Integration of AI and machine learning algorithms in welding equipment optimizes parameters for different materials and thicknesses.

Analyst Insight: The increasing demand for these equipment in metal welding contributes to the market growth.

Business Case: A construction firm adopted AI-driven welding systems, resulting in a 40% improvement in weld quality and a 35% reduction in rework costs.

1. Technological Innovation

Companies are investing heavily in R&D to develop advanced equipment that integrates AI, IoT, and machine learning. For instance, TRUMPF's TruMatic 5000 manufacturing cell, unveiled in October 2023, offers fully automated laser-cutting, punching, and forming with a six-kilowatt fiber laser for optimal productivity and energy efficiency.

2. Regional Expansion

Asia Pacific is estimated to contribute 56% to the growth of the global market during the forecast period, driven by the increasing utilization of this equipment in countries like China, Japan, India, Taiwan, and South Korea.

3. Strategic Alliances

Collaborations between technology providers and equipment manufacturers are enhancing product offerings. For example, TRUMPF and Sima.ai partnered to develop lasers with AI capabilities, integrating features such as marking, cutting, welding, and powder metal 3D printing.

Expert Quote: "The integration of AI and IoT in sheet metal processing equipment is not just a trend; it's a paradigm shift that will define the industry's future." – Industry Expert.

The Sheet Metal Processing Equipment Market is expanding rapidly, driven by increasing demand for high-precision metal fabrication across sectors like automotive, construction, and aerospace. Core technologies such as laser cutting, plasma cutting, and waterjet systems are widely used to shape and process sheet metal, including steel sheets and metal alloys. Alongside cutting tools, CNC machines, punching machines, and bending presses play a vital role in improving productivity and efficiency. The adoption of coils handling equipment, edge trimming solutions, and deburring tools ensures smoother operations and cleaner finishes. Innovations in fabrication software further streamline workflow, enabling manufacturers to achieve precise outputs with minimal errors. As demand rises, so does the usage of cutting fluids and abrasive wheels to enhance the life of tools and ensure superior quality.

1. Autonomous Manufacturing

By 2028, fully autonomous sheet metal processing lines are expected to become mainstream, reducing human intervention and increasing efficiency.

2. Sustainable Practices

The adoption of eco-friendly materials and energy-efficient technologies will be a key focus, aligning with global sustainability goals.

3. Customization at Scale

Advancements in 3D printing and AI will enable mass customization of sheet metal components, catering to specific customer requirements.

Company Example: Amada Holdings Co., Ltd. has introduced an automated sheet metal processing line that integrates laser cutting, bending, and material handling, enhancing productivity and reducing cycle times.

As automation and AI redefine the sheet metal processing landscape, are traditional manufacturers prepared to embrace these transformative changes?

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

1. Embrace AI-Driven Automation

Invest in AI-powered equipment to enhance precision and reduce operational costs.

2. Prioritize Sustainability

Adopt eco-friendly materials and energy-efficient technologies to align with global sustainability goals.

Research within the Sheet Metal Processing Equipment Market is focused on advanced precision tools, tooling systems, and automation technologies to boost processing speed and consistency. Processes such as metal stamping, spot welding, and seam welders are being optimized with high-tech welding robots and hydraulic presses for faster throughput. Components like stamping dies, forming tools, and shearing blades are continually being refined for improved performance in handling materials like aluminum processing. In addition, surface treatment and metal finishing innovations are enhancing the durability and aesthetic quality of finished parts. Automation and robotics integration is also streamlining roll forming, while new applications of sheet metal processing are emerging in industries where accuracy and strength are paramount. This research supports the development of smarter, more efficient systems that align with future manufacturing demands.

Safe and Secure SSL Encrypted