Polyvinylidene Fluoride (PVDF) Market Size, Growth, and Trends: 2024–2028 Strategic Insights

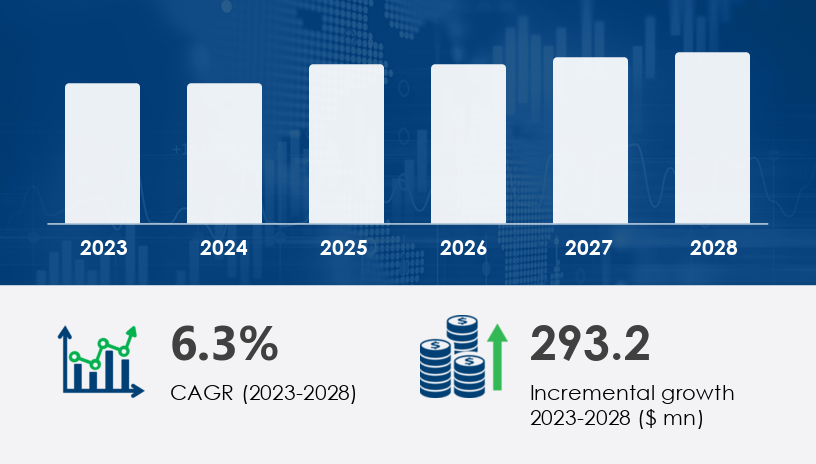

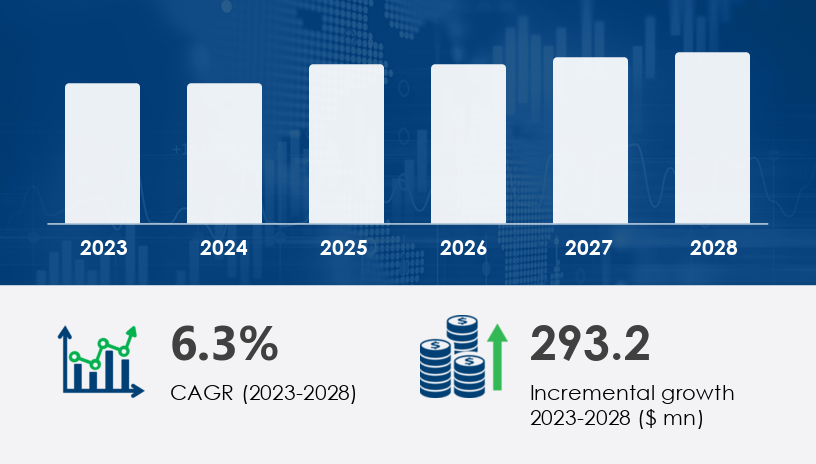

The global Polyvinylidene Fluoride (PVDF) market is undergoing significant expansion, projected to grow by USD 293.2 million at a CAGR of 6.3% from 2023 to 2028. This versatile fluoropolymer, known for its chemical resistance, biocompatibility, and piezoelectric properties, is witnessing increased demand in industries such as automotive, electronics, construction, and healthcare. As the world transitions towards advanced materials that offer greater durability and efficiency, PVDF is emerging as a key player in various high-performance applications.

The PVDF market’s growth trajectory is being largely driven by technological advancements in sectors like electric vehicles (EVs), electronics, and construction. In this comprehensive guide, we delve into how PVDF's unique properties are reshaping these industries and what the future holds for this promising material.

For more details about the industry, get the PDF sample report for free

Market Research Overview

The Polyvinylidene Fluoride (PVDF) Market is poised for significant growth due to its extensive applications across diverse industries. PVDF is available in various forms, including homopolymer PVDF, copolymer PVDF, PVDF powder, and PVDF pellets, each offering unique properties that cater to specific needs. The versatility of PVDF is demonstrated in applications such as lithium-ion batteries, where it is used as a battery binder in electrode formulations and separator coatings. Additionally, PVDF's chemical resistance, thermal stability, flame resistance, and UV stability make it an ideal choice for demanding environments. Industries such as chemical processing, oil extraction, and semiconductor components benefit from PVDF's corrosion resistance and mechanical strength. PVDF films and membranes are increasingly used in water filtration and gas separation applications, while PVDF's high crystallinity enhances its performance in photovoltaic films and bioethanol recovery processes.

What is Polyvinylidene Fluoride (PVDF)?

Polyvinylidene Fluoride (PVDF) is a highly versatile fluoropolymer, a type of plastic that’s prized for its superior chemical resistance, high-temperature tolerance, and biocompatibility. PVDF is a thermoplastic polymer produced through the polymerization of vinylidene fluoride. Its structure consists of alternating carbon and fluorine atoms, giving it exceptional properties like:

-

Thermal and electrical conductivity

-

Hydrophobicity

-

Flame resistance

-

Gas and water impermeability

-

Piezoelectric effect (ability to generate electricity under stress)

These characteristics make it an ideal choice for a range of demanding applications, from medical devices to aerospace components, lithium-ion batteries, and protective coatings.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report.

Polyvinylidene Fluoride (PVDF) Market Segmentation

The PVDF market is segmented into key categories such as type and region, each contributing uniquely to the market’s growth. Below, we break down these segments and discuss their market outlook from 2024 to 2028.

By Type: Homopolymer vs. Copolymer

Homopolymer PVDF: This type of PVDF is expected to dominate the market, driven by its superior strength, stiffness, and heat deflection properties. It is widely used in industries such as aerospace, electronics, and automotive for applications including pipes, films, membranes, and wire coatings. Homopolymer PVDF’s higher purity makes it an ideal choice for sectors requiring extreme durability and resistance to environmental factors.

Copolymer PVDF: Copolymer PVDF offers improved flexibility and lower cost compared to homopolymer, making it more suitable for applications in areas such as films, coatings, and seals.

| Type |

Projected Growth |

Applications |

Key Industries |

| Homopolymer |

Significant growth |

Pipes, coatings, batteries, aerospace |

Aerospace, Electronics, Automotive |

| Copolymer |

Moderate growth |

Films, gaskets, medical devices |

Medical, Packaging |

By Region: Dominance of APAC

The global market is segmented into the following regions:

- APAC

- North America

- Europe

- Middle East and Africa

- South America

APAC (Asia-Pacific) is set to lead the PVDF market, accounting for 61% of the global growth during the forecast period. The growing demand for PVDF in China, India, and Japan is being fueled by the surge in demand for electric vehicles (EVs), electronics, and construction materials. China’s strong automotive and electronics sectors, along with its booming construction industry, are prime drivers of PVDF consumption.

North America and Europe will also experience steady growth, driven by the increasing adoption of PVDF in industries such as medical devices, aviation, and energy.

Market Drivers and Trends: What’s Shaping the PVDF Industry?

Key Market Drivers

-

Advancements in the Construction Sector: PVDF’s exceptional durability and resistance to weathering make it a popular choice for construction applications, including roofing, piping, and coatings. As infrastructure projects worldwide expand, especially in regions like APAC and North America, demand for PVDF is expected to rise.

-

Growing Demand for Electric Vehicles (EVs): As the automotive industry pivots toward electric vehicles, lithium-ion batteries—a crucial component in EVs—are increasingly incorporating PVDF due to its high chemical resistance and electrical conductivity.

-

Rising Electronics Production: PVDF’s use in semiconductors, mobile device enclosures, and sensors is accelerating as the demand for smaller, lighter, and more efficient electronic products grows. The market’s shift towards thinner, smarter devices makes PVDF a go-to material for manufacturers seeking improved performance.

-

Medical and Biocompatible Applications: PVDF’s biocompatibility and biostability make it ideal for use in medical devices, including hernia meshes, sutures, and drug delivery systems. As healthcare needs continue to rise, PVDF’s presence in the medical industry will expand.

Emerging Trends

-

Miniaturization in Electronics: The growing trend toward smaller and more powerful electronics drives demand for PVDF in miniaturized components like sensors, connectors, and circuit boards.

-

Sustainability Efforts: As industries focus on reducing their environmental footprint, PVDF’s longevity and recyclability offer a sustainable alternative to other polymers that degrade over time.

Try a Free Report Sample Now

Risks and Challenges in the PVDF Market

High Production Costs

One of the primary challenges for the PVDF market is its high production cost. PVDF is more expensive to produce compared to commodity plastics, primarily due to the raw material costs associated with vinylidene fluoride monomer. These higher costs can deter small and medium-sized enterprises (SMEs) from incorporating PVDF into their products, limiting its adoption across certain sectors.

Complex Manufacturing Process

The polymerization process required to create high-quality PVDF can be complex, requiring significant investment in specialized machinery and expertise. This manufacturing complexity contributes to both higher production costs and limited supply availability, posing a challenge to market expansion.

Research Analysis Overview

Research analysis indicates that PVDF's biocompatible properties have expanded its use in the medical field, particularly in applications like hernia meshes, suture materials, and drug delivery systems. The material’s piezoelectric properties further support its use in aerospace fittings and advanced manufacturing techniques such as injection molding. PVDF's versatility also extends to the production of high-performance products like wire insulation, cable insulation, and piping systems, where it ensures long-lasting durability and superior weather resistance. As industries shift toward smart manufacturing and more sustainable practices, PVDF's role in filtration membranes, medical tubing, and architectural coatings continues to grow. The material’s widespread use across sectors, from aerospace to pharmaceutical applications, is driven by its excellent dielectric strength, mechanical strength, and adaptability to a range of harsh environmental conditions, ensuring its position as a critical material in global markets.

Strategic Takeaways: Navigating the PVDF Market’s Future

Focus on Cost Reduction through Innovation

With PVDF’s high cost posing a barrier to widespread adoption, companies need to focus on reducing production costs through technological innovations. Research into alternative production methods or new, cost-effective raw materials could unlock significant growth opportunities.

Diversification into New Applications

To tap into the full potential of PVDF, companies should explore new markets and applications, particularly in emerging sectors like renewable energy, biomaterials, and advanced coatings. Research and development (R&D) initiatives will play a crucial role in enabling the discovery of novel uses for PVDF.

Get more details by ordering the complete report

Mini Case Study: PVDF in the Electric Vehicle Industry

A major automotive manufacturer recently began using PVDF in the production of lithium-ion batteries for electric vehicles. By leveraging PVDF’s superior thermal stability and chemical resistance, the company was able to increase the battery’s lifetime and efficiency. This has resulted in improved performance metrics, with a reported 15% increase in energy density for their EV batteries. The use of PVDF not only provided a performance boost but also aligned with the company’s goals of incorporating sustainable materials into their EVs.

Future Implications: What’s Next for PVDF?

As industries increasingly demand advanced materials that combine durability, performance, and biocompatibility, PVDF is poised to play a central role in various high-tech sectors. The electric vehicle revolution and the rise of smart electronics are two key factors that will drive PVDF adoption over the next decade.

Expert Predictions

Industry experts predict that advancements in PVDF synthesis will lead to the development of more affordable and flexible variants of the material, making it accessible for a wider range of applications. This evolution could reshape the market dynamics, enabling cost-effective use of PVDF in industries currently limited by its high production cost.

Actionable Recommendations

-

Invest in R&D: To stay ahead in a rapidly evolving market, companies should prioritize investment in R&D, focusing on cost reduction and new applications for PVDF.

-

Expand into Emerging Markets: Companies should target high-growth regions like Asia-Pacific and South America, where the demand for high-performance polymers is expanding across industries such as automotive, electronics, and construction.

- Partnerships and Collaborations: By collaborating with universities and research institutions, businesses can accelerate innovative breakthroughs in PVDF materials and technologies.

Conclusion

The Polyvinylidene Fluoride (PVDF) market is on a transformative path, fueled by industrial innovation, environmental demands, and a global push toward efficiency and biocompatibility. While high production costs pose challenges, the opportunities outweigh the obstacles—particularly as R&D paves the way for more cost-effective solutions.