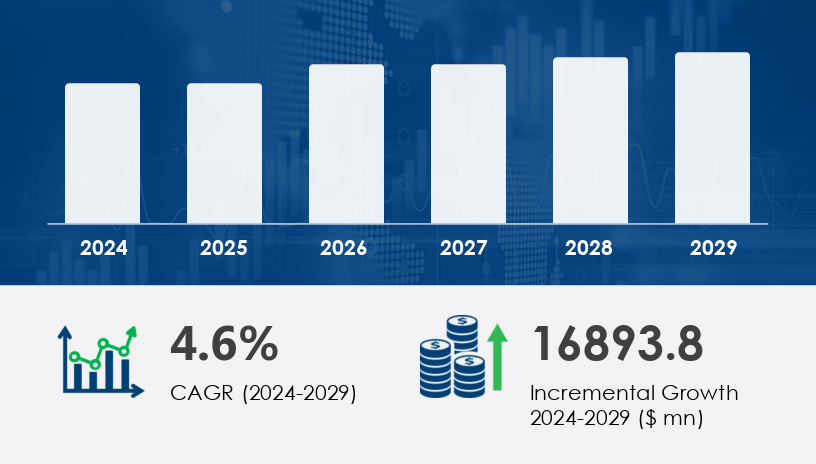

The global plywood market is forecast to expand by a staggering USD 16.89 billion between 2025 and 2029, registering a CAGR of 4.6%, underscoring the material’s growing prominence across residential, commercial, and industrial construction. This surge reflects broader trends in urbanization, infrastructure upgrades, and the rapid shift toward sustainable and engineered wood solutions.This 2025 Outlook offers a comprehensive guide to key trends, challenges, and actionable strategies shaping the plywood industry, with sharp expert commentary and market segmentation analysis.

For more details about the industry, get the PDF sample report for free

Plywood, a high-strength engineered wood product, is foundational in applications ranging from home interiors to large-scale infrastructure projects. Manufactured by gluing thin layers of wood veneer at alternating angles, plywood offers exceptional dimensional stability, moisture resistance, and versatility. Its adaptability to CNC machining and laser cutting further extends its utility in precision-based architectural and furniture design.

The current growth trajectory is largely fueled by infrastructure investments in both mature and developing economies. In the United States, demand is surging for fire-rated plywood, cross-laminated timber (CLT), and LEED-compliant materials. In emerging markets like India and China, smart city missions and public housing initiatives are expanding the plywood customer base.

The Asia-Pacific region is projected to account for 64% of global plywood market growth through 2029. China, India, and Southeast Asia are seeing rapid urbanization, housing booms, and rising disposable incomes. In India, policies such as PMAY, Smart Cities Mission, and Swachh Bharat are not only transforming urban infrastructure but also accelerating demand for moisture-resistant and fire-retardant plywood for sustainable building applications.

Government support in terms of foreign direct investment (FDI) and large-scale industrialization are transforming plywood from a commodity material into a strategic asset for modern construction.

Get more details by ordering the complete report

The hardwood plywood segment is expected to see the most substantial growth during the forecast period. Known for its durability and strength, hardwood plywood is widely used in furniture manufacturing, cabinetry, wall cladding, and load-bearing construction.

Industry insiders note that innovations in plywood finishing, such as formaldehyde-free adhesives and enhanced waterproofing, are driving customer preference. According to a senior analyst at a leading forestry research institute, “As environmental compliance tightens, manufacturers who invest in sustainable hardwood sourcing and low-emission products will win customer trust and market share.”

The construction industry is the strongest catalyst for plywood demand. In the U.S., renovations and new housing projects continue to climb, while Asia sees massive investments in office buildings and real estate development. Plywood plays a vital role in sheathing, roofing, furniture, and interior design, offering a cost-effective and efficient building solution.

The rise of modular and prefabricated construction is reshaping the material supply chain. Lightweight, high-performance, and precision-cut plywood components enable faster project timelines and reduced waste. Furthermore, LEED certification requirements are prompting developers to opt for eco-friendly plywood products, particularly those with fire-retardant and moisture-resistant ratings.

One of the major headwinds is the rising wage structure in key manufacturing hubs like China, India, Vietnam, and Indonesia. These economies, while growing, are experiencing shrinking cost advantages for global plywood exporters. This shift is nudging producers toward automation, lean manufacturing, and cost-effective material sourcing.

Despite its durability, plywood remains vulnerable to fluctuating humidity levels, especially during installation. Flooring applications are particularly susceptible. Manufacturers provide relative humidity (RH) guidelines—often between 35%-55%—to ensure optimal performance. Failing to adhere can result in warping, delamination, or structural weakening.

For example, using plywood flooring at 40% RH in an environment with 30% RH, without proper adjustment or sealing, can compromise product integrity. These challenges underscore the importance of ongoing R&D in moisture control and treatment technologies.

For more details about the industry, get the PDF sample report for free

Invest in R&D: Focus on enhancing water-resistant and formaldehyde-free adhesives to boost performance and compliance.

Diversify Manufacturing: Reduce dependency on high-wage countries by exploring regional production hubs or automation.

Strengthen Certifications: Achieve industry certifications (e.g., FSC, LEED, EPA standards) to unlock premium markets.

Adopt Digital Sales: Expand into online plywood sales and leverage digital platforms for B2B and retail growth.

The plywood industry is experiencing a transition from commodity-based production to engineered, high-performance materials. Innovative formats like glulam beams, CLT panels, and composite plywood are being developed to meet stringent architectural standards.

Sustainability is a dominant trend, with an emphasis on recyclable materials, carbon footprint reduction, and sustainable forestry. Customers are increasingly opting for products that align with both their performance expectations and environmental values.

Get more details by ordering the complete report

A construction company in Oregon adopted CLT and moisture-resistant plywood for a 50-unit modular housing project. The use of CNC-cut hardwood plywood panels reduced waste by 18% and project timelines by 22%. LEED Gold certification was achieved due to the use of low-emission and recyclable materials, reinforcing plywood’s role in sustainable housing solutions.

The plywood market continues to evolve with significant demand across various applications and material types. Key product categories such as softwood plywood and hardwood plywood dominate the landscape due to their structural versatility. Marine plywood is gaining attention for high-moisture environments, while specialty options like birch plywood, oak plywood, and maple plywood are widely used in high-end carpentry and cabinetry. In residential construction, pine plywood and cedar plywood are common, while mahogany plywood and teak plywood cater to premium segments. Bamboo plywood has emerged as a sustainable alternative, reflecting the industry’s shift towards eco-friendly materials. Product innovations include phenolic plywood, known for its durability, and laminated plywood used in furniture and wall panels. Veneered plywood and structural plywood serve diverse building applications, while exterior plywood and interior plywood are tailored for specific exposure conditions. Furniture plywood and cabinet plywood are staples in the interior design and modular furniture sectors. Meanwhile, flooring plywood, roofing plywood, sheathing plywood, and subfloor plywood address key structural needs. Decorative plywood and flexible plywood are becoming more popular in creative applications, and fire-retardant plywood and moisture-resistant plywood cater to safety and durability requirements in commercial and residential construction.

For more details about the industry, get the PDF sample report for free

Leading players in the plywood market are focusing on partnerships, product launches, and regional expansion to maintain competitiveness. Notable companies include:

Boise Cascade Co

Century Plyboards India Ltd.

Columbia Forest Products Inc.

Greenply Industries Ltd.

Weyerhaeuser Co.

Kronospan

UPM-Kymmene Corp.

Duroply Industries Ltd.

METSA Group

These firms are pursuing technological advancements, including better adhesives, formaldehyde regulation compliance, and AI-driven quality control systems in plywood production lines.

The next decade will see a decisive shift toward digitization, sustainable sourcing, and green construction alignment. As building codes become more stringent, and as climate adaptation drives innovation, plywood’s performance under extreme conditions will become a differentiating factor.

Companies that adapt to changing regulations, enhance eco-performance, and integrate smart production techniques will command the highest margins and market share.

Get more details by ordering the complete report

Analytical insights into the plywood market reveal growing segmentation by product specifications and chemical composition. Market participants evaluate a broad range of options including plywood panels, plywood sheets, and plywood grades to meet application-specific requirements. Top-tier selections like AA grade plywood offer premium finish and strength, while BB grade plywood and CDX plywood provide cost-effective solutions for construction and subflooring. Chemical bonding agents play a critical role, with phenolic resin enhancing water resistance, urea-formaldehyde used in interior applications, and melamine adhesive ensuring strong bonding in laminates. The market also emphasizes material layering technologies such as wood veneer finishes, cross-laminated timber for structural integrity, and engineered wood products designed for stability. Core materials such as plywood core, particle board, and MDF board are evaluated for cost, weight, and performance. LVL beams are frequently used in framing, while plywood edging and plywood laminates are essential for creating polished surfaces in furniture and cabinetry. This diversification reflects a comprehensive approach to product development, meeting the expanding demand for functional, durable, and aesthetically appealing plywood solutions across both commercial and residential construction environments.

Plywood is no longer just a commodity—it’s a strategic material powering modern construction. From urban housing to marine applications, its relevance is growing in scope, complexity, and sustainability. For stakeholders—from architects to distributors—the time to act is now.

Safe and Secure SSL Encrypted