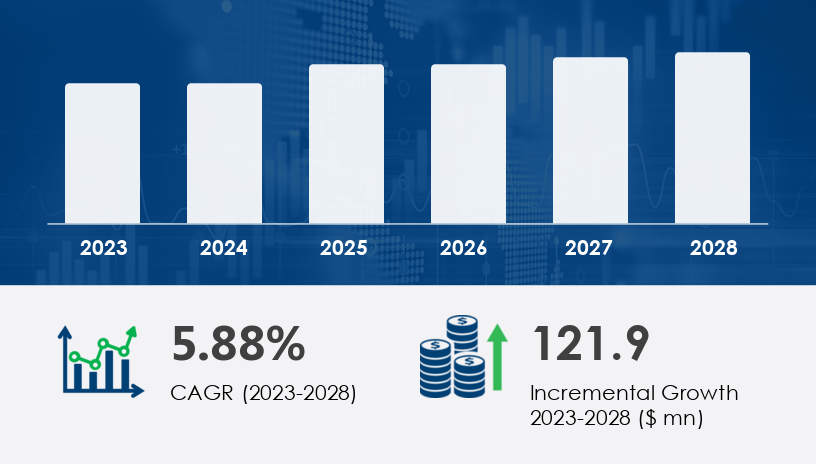

As the global oil and gas industry navigates a complex landscape of price volatility, environmental pressure, and operational efficiency, one overlooked but mission-critical component is stepping into the spotlight: oilwell spacer fluids. These viscous intermediates—inserted between drilling muds and cement slurries—are no longer just functional fluids; they are becoming strategic enablers of well integrity, zonal isolation, and overall operational excellence. Between 2023 and 2028, the oilwell spacer fluids market is projected to grow by USD 121.9 million, representing a Compound Annual Growth Rate (CAGR) of 5.88%, according to Technavio. This growth trajectory positions the market for significant strategic opportunity between 2025 and 2029.

For more details about the industry, get the PDF sample report for free

Oilwell spacer fluids are indispensable in modern drilling operations, especially during the cementing phase. They are carefully engineered to displace drilling fluids from the wellbore and create a clean interface for cement slurries to bond effectively. This action is critical for maintaining zonal isolation, preventing cross-contamination between geological layers, and ensuring well longevity. The market includes a variety of formulations—self-healing cements, water-based fluids, and oil-based fluids—each tailored for specific well conditions and environmental considerations.

The core value proposition of these fluids is becoming more pronounced as oil and gas companies pursue deeper and more complex reservoirs, especially onshore where operational costs are comparatively lower. Cementing failures due to poor spacer fluid performance can lead to catastrophic blowouts or well abandonment, making investment in high-quality spacer fluids a non-negotiable safety and economic imperative.

A clear trend shaping this market is the technological evolution of cementing solutions, particularly with self-healing cement technology. This innovation addresses a longstanding challenge: micro-cracks that develop in cement sheaths under high-pressure conditions. Self-healing cements contain additives that swell upon contact with hydrocarbons or water, sealing fractures autonomously. This is especially critical in deepwater and high-temperature/high-pressure (HTHP) environments where conventional cement systems struggle.

Simultaneously, water-based spacer fluids are gaining traction due to rising environmental concerns. Unlike their oil-based counterparts, water-based formulations are biodegradable and pose a lower risk to surrounding ecosystems. This trend is reinforced by increasingly stringent environmental regulations and corporate ESG commitments, pushing companies toward sustainable alternatives. We’re also witnessing a shift in chemical formulations used in spacer fluids to ensure compatibility with advanced casing pipes and new-generation drill strings.

Get more details by ordering the complete report

The onshore segment of the market is poised for significant growth between 2025 and 2029. Historically valued at USD 233 million in 2018, this segment continues to benefit from lower overhead costs, tax incentives, and easier logistical access compared to offshore operations. The increasing number of active onshore wells—spurred by global energy demand—is directly translating into greater demand for effective spacer fluids.

Onshore drilling also aligns with the adoption of water-based systems. Companies are increasingly using these fluids in response to environmental pressures, further bolstered by government subsidies and policy incentives. Meanwhile, offshore drilling, though more capital-intensive, is expected to adopt smarter, performance-optimized fluids like self-healing cements that reduce the risks and costs of remedial cementing.

North America is expected to contribute nearly 30% of the global oilwell spacer fluids market growth through 2028, with the United States and Canada leading the charge. The U.S., in particular, benefits from a robust upstream oil and gas sector, supported by policy incentives and private-sector investment. Companies are actively investing in advanced drilling technologies, including high-performance spacer fluids, to maximize well efficiency and longevity.

Beyond North America, Asia-Pacific (APAC) and the Middle East & Africa (MEA) are emerging as high-growth regions. China’s expanding LNG infrastructure and the Middle East’s renewed push into both traditional hydrocarbons and cleaner energy technologies are creating opportunities for dual-purpose spacer fluids that balance performance with environmental compliance.

For more details about the industry, get the PDF sample report for free

The biggest headwind facing the oilwell spacer fluids market is the volatile nature of crude oil prices. Market instability directly impacts exploration and production (E&P) budgets, often leading to deferred drilling and a slowdown in demand for consumables like spacer fluids. For instance, the 2020 oil price crash severely affected upstream investments, with many projects postponed or canceled.

Moreover, the capital-intensity of remedial cementing, which becomes necessary when primary cementing fails, adds another layer of financial risk. The adoption of more advanced but costlier fluid systems may face resistance during periods of low crude prices. Thus, companies must balance cost-efficiency with performance and long-term well integrity.

Key players such as Aubin Ltd., Baker Hughes, Schlumberger, BASF SE, and Halliburton are investing heavily in R&D to create next-generation spacer fluids. Aubin Ltd., for instance, offers products like CSP-500 and CSS-01, which are designed to enhance both drilling efficiency and cement bonding strength, critical parameters for long-term well performance.

Partnerships, mergers, and strategic alliances are common as companies seek to expand their geographic footprint and technology portfolio. The competitive matrix includes a mix of pure-play chemical manufacturers, oilfield service giants, and specialized drilling fluid providers. Their success hinges not just on product quality but also on advisory services, customization capabilities, and regulatory compliance support.

For more details about the industry, get the PDF sample report for free

The Oilwell Spacer Fluids Market is a critical segment within upstream oil and gas operations, essential for ensuring wellbore stability and effective zonal isolation during primary cementing and remedial cementing. These fluids act as a buffer between drilling fluids and cement slurry to prevent fluid contamination and enhance cement bonding. Used extensively with casing pipe to support mud displacement and well completion, modern spacers are developed for compatibility with high-salinity environments, high-temperature spacers, and HPHT wells. Innovations like bio-based spacers, eco-friendly spacers, and high-performance spacers contribute to environmental compliance and minimize formation damage. The growing use of smart cement and self-healing cement is driving demand for advanced formulations of spacer fluids, particularly in shale exploration, deepwater drilling, and unconventional resources

Looking forward, the oilwell spacer fluids market is likely to evolve across three main axes:

Product Customization: As wells become more complex, demand will rise for tailor-made fluid systems that accommodate site-specific geology and operational constraints. Expect to see more modular chemical packages that can be quickly adjusted on-site.

Digital Integration: Spacer fluids may soon benefit from digital modeling and AI-driven performance simulations, enabling operators to predict outcomes before deployment. This will enhance precision and reduce the trial-and-error that currently adds cost and risk.

Sustainability Leadership: The pivot toward low-toxicity, biodegradable spacer fluids will become a major differentiator. Companies that can deliver on ESG goals without compromising on performance will command premium market share.

For more details about the industry, get the PDF sample report for free

For stakeholders looking to capitalize on the growth of the oilwell spacer fluids market between 2025 and 2029, here are five strategic imperatives:

Invest in R&D focused on smart cement and environmentally friendly spacer fluids.

Build advisory and on-site services to differentiate from commodity competitors.

Strengthen supply chains in high-growth regions such as APAC and MEA.

Collaborate with regulatory bodies to fast-track approval of new formulations.

Leverage digital tools for performance forecasting and risk mitigation.

Current trends in the Oilwell Spacer Fluids Market are heavily influenced by increasing exploration activities, active rig count, and the need for enhanced production efficiency and drilling efficiency. Specialized spacers are designed for complex wellbore conditions, aiding in the mitigation of fluid migration and preserving cement sheath integrity. Key technologies include oil-based spacers, gas-based spacers, and additives such as rheology modifiers, demulsifiers, and fluid separation agents. These components contribute to wellbore cleanup and maintain operational safety across a variety of terrains and drilling technologies. Spacer fluids are integral to supporting the performance of hydraulic fracturing operations and safeguarding well integrity. As energy operators seek solutions for environmental compliance and long-term durability, the market continues to pivot toward spacer formulations that are efficient, reliable, and adaptable to increasingly challenging drilling environments

For more details about the industry, get the PDF sample report for free

The oilwell spacer fluids market is far more than a support segment in the oilfield services ecosystem—it’s a vital enabler of well success and environmental responsibility. As the industry embraces smarter, greener, and more efficient solutions, spacer fluids will serve as both a technical safeguard and a strategic asset. Between 2025 and 2029, companies that align innovation with sustainability, and adapt quickly to shifting market dynamics, will be best positioned to lead this evolving frontier.

Safe and Secure SSL Encrypted