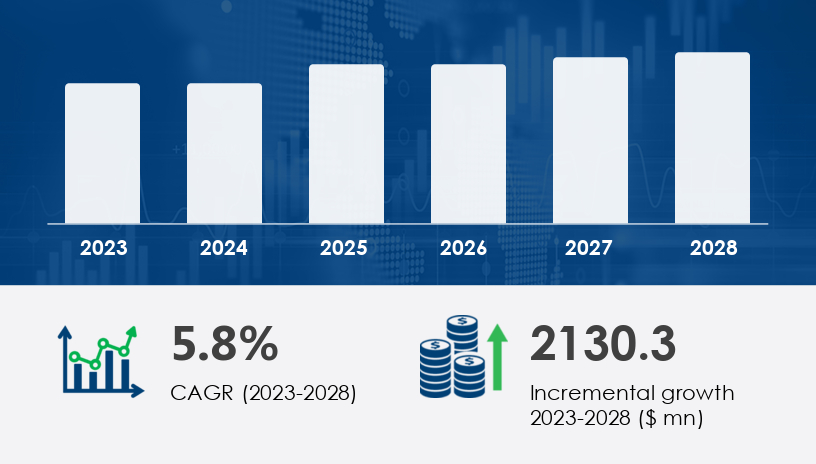

The nonwoven filter media market is set to grow by USD 2.13 billion between 2023 and 2028, achieving a projected compound annual growth rate (CAGR) of 5.8%. This expansion reflects the rising demand across HVAC, automotive, water treatment, and hygiene sectors — industries increasingly reliant on advanced filtration solutions.In this 2025 Outlook, we explore key market dynamics, breakthrough technologies, and strategic pathways that are reshaping the nonwoven filter media industry. From cutting-edge nano-fiber technologies to surging APAC demand, this comprehensive guide offers authoritative analysis for decision-makers and stakeholders.For more details about the industry, get the PDF sample report for free

Nonwoven filter media refers to engineered fabrics made from fibers bonded together by chemical, mechanical, heat, or solvent treatment rather than weaving or knitting. These materials offer superior filtration capabilities, breathability, and cost-efficiency.

They are integral to:

Air filtration in HVAC and automotive systems

Liquid filtration in food and beverage, water treatment, and healthcare

Particulate filtration in industrial and chemical processing applications

“HVAC systems are evolving from luxury to necessity, especially with growing air quality concerns,” explains Senior Technavio Expert. “This puts nonwoven media at the heart of global urban infrastructure.”

HVAC installations are driving demand for nonwoven filter media due to:

Their efficiency in trapping dust, pollen, and microbes

Longer lifecycle compared to traditional woven filters

Compatibility with energy-efficient air handling units (AHUs)

In water treatment, nonwoven media are used in reverse osmosis and municipal filtration.

In automotive, cabin and engine air filters, oil filters, and fuel filters rely on these media.

Healthcare and PPE use nonwovens for sterilized wipes, facemasks, and air filtration.

Get more details by ordering the complete report

Driven by industrialization and urbanization, countries like China, India, and South Korea are pushing APAC to the forefront of the nonwoven filter media market.

As a key contributor to the industrial wastewater equipment market, China’s push for clean water infrastructure fuels a soaring demand for high-performance liquid filtration solutions — most notably, nonwoven filter media in municipal systems.

In North America, especially the U.S., nonwoven media are vital for automotive filters and smart HVAC systems. Innovations like variable refrigerant flow (VRF) and electrostatic air purification are accelerating domestic demand.

Despite wide adoption, nonwoven filter media face limitations in energy sectors like gas turbines and offshore platforms due to:

Frequent replacements

System downtimes during maintenance

Cost inefficiencies vs. alternatives like Wetlaid or Needlepunch filters

These challenges call for next-gen materials that balance performance with durability and maintenance economy

For more details about the industry, get the PDF sample report for free

Companies like Freudenberg Filtration Technologies GmbH & Co. KG are pioneering new media such as sinTexx Plus, a nanofiber-coated polyester with:

Extended lifecycle

Enhanced pollutant capture

Improved energy efficiency

Such advances are key to tackling indoor air pollution, which WHO ranks as a leading contributor to respiratory disease worldwide.

“Longevity, low-pressure drop, and environmental safety are the next frontiers in nonwoven filter innovation,” notes Senior Technavio Expert.

Get more details by ordering the complete report

The Nonwoven Filter Media Market has seen significant growth due to increasing demand for efficient nonwoven filter technologies across various sectors. Key materials driving this market include meltblown fabric, spunbond material, polypropylene filter, and polyester nonwoven, all known for their high filtration efficiency. Applications such as air filtration, liquid filtration, and HVAC filter systems are witnessing a surge, particularly in residential, industrial, and commercial settings. The healthcare sector relies on medical filtration and pharmaceutical filter solutions, while the automotive industry benefits from durable automotive filter technologies. Water treatment needs are met through water purification systems, dust collector units, and high-performance filters like HEPA filter and ULPA filter. The inclusion of activated carbon and nanofiber filter elements further enhances contaminant capture. Technologies such as membrane filtration, baghouse filter, and cartridge filter support a broad range of applications requiring both depth filtration and surface filtration across industrial processes.

Invest in Nanofiber R&D: Tap into rising demand in healthcare and high-efficiency HVAC systems.

Target APAC Expansion: Localize production in China and India to reduce supply chain risk.

Bundle With Smart Systems: Position nonwoven media alongside energy-efficient HVAC solutions.

Address Sustainability: Develop biodegradable or recyclable nonwoven materials to appeal to ESG-focused buyers.

Raw material price volatility, especially polymers and resins

Environmental regulations affecting disposal and emissions

Competitive pressure from advanced filter technologies

Companies must hedge these risks through vertical integration, material innovation, and strategic alliances.

For more details about the industry, get the PDF sample report for free

From a research analysis standpoint, advancements in materials such as electrospun fiber, synthetic fiber, cellulose nonwoven, and glass fiber are influencing the development of specialized filter media. High-performance components like the ceramic filter, pleated filter, and systems for oil filtration and gas turbine filter demonstrate the sector's technical evolution. The expansion into industrial filtration, food filtration, and beverage filtration is further supported by materials like microfiber fabric, wetlaid nonwoven, drylaid material, and spunlace fabric. Binding technologies such as thermal bonded and chemical bonded processes help maintain structural integrity. The market also demands filters with unique properties including antistatic filter, flame-retardant fabric, hydrophobic filter, and hydrophilic nonwoven, which are tailored for niche uses in safety-critical or high-moisture environments. These innovations continue to improve the effectiveness and versatility of nonwoven filter media in a wide range of filtration applications.

The nonwoven filter media market is not just expanding — it is transforming. From nanofiber revolutions to growing APAC dominance, the sector is central to solving critical challenges in clean air, water, and health safety.Whether you're a manufacturer, investor, or policymaker, understanding this space is crucial.

Safe and Secure SSL Encrypted