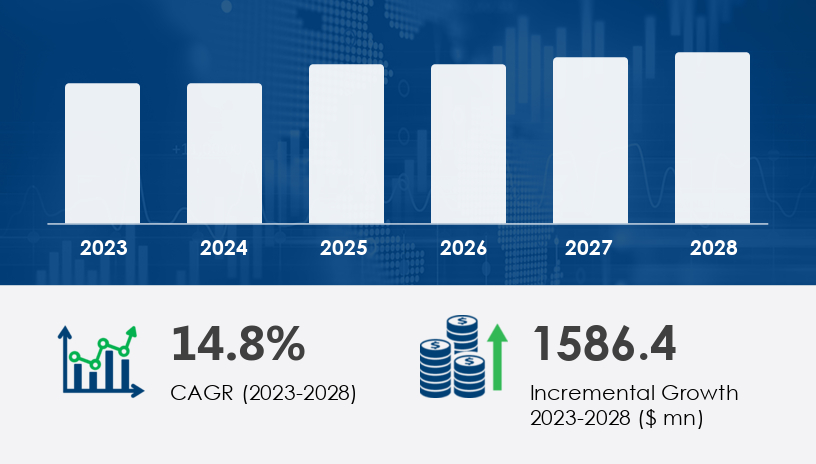

The Moving Bed Bioreactor (MBBR) market is projected to grow by USD 1.59 billion between 2023 and 2028, surging at a CAGR of 14.8%. Discover why this innovative wastewater treatment technology is gaining global traction, particularly in regions facing acute water scarcity and tightening environmental regulations. The 2025 outlook reveals strong momentum driven by sustainability imperatives, cutting-edge innovations, and industrial demand for compact, low-maintenance solutions.

For more details about the industry, get the PDF sample report for free

A Moving Bed Bioreactor (MBBR) is a wastewater treatment system that uses biofilm-covered plastic carriers suspended in an aeration tank to enhance microbial activity for treating organic pollutants. Its design facilitates nitrification, denitrification, and organic matter breakdown, making it highly effective for both municipal and industrial applications.

The Moving Bed Bioreactor (MBBR) Market is gaining significant traction globally due to rising demand for efficient wastewater treatment solutions across both industrial wastewater and municipal wastewater sectors. This biological treatment system uses biofilm carriers, typically made from high-density polyethylene, which provide a large biocarrier surface area for microbial growth. As a biological process, MBBR enables the nitrification process, denitrification process, and effective organic matter breakdown. Configurations like aerobic MBBR and anaerobic MBBR are used based on treatment needs, with aeration systems, plastic media, and a well-designed mixing mechanism playing key roles in optimizing oxygen supply and biofilm development. The technology supports nutrient removal, including phosphorus removal, and addresses challenges in pharmaceutical wastewater and hospital wastewater through its adaptable design. With advantages such as compact footprint, treatment capacity, and support for sustainable treatment, MBBR aligns well with circular economy principles.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report

Across geographies, nations are grappling with water stress. Regulatory bodies like the U.S. Environmental Protection Agency (EPA) are pushing for water reuse under mandates like the Clean Water Act (CWA). MBBRs provide a compact, energy-efficient method to treat wastewater for reuse in industries, firefighting, or cooling systems.

From beverage factories in Texas to textile plants in India, MBBR systems help industries meet stringent discharge norms. Their small footprint, lower maintenance, and modular design make them ideal for retrofitting into existing plants.

A major U.S.-based soft drink manufacturer implemented an MBBR system in its Georgia facility to address growing wastewater loads. The result?

30% reduction in discharge costs

95% organic matter removal efficiency

System downtime cut in half compared to traditional activated sludge systems

This transformation illustrates why MBBR is not just an environmental asset but also a financial advantage.

| Segment | Growth Outlook |

|---|---|

| Municipal Wastewater | High |

| Food & Beverage | Moderate |

| Pulp and Paper | Moderate |

| Healthcare | Emerging |

| Others | Stable |

Municipal wastewater is the largest and fastest-growing segment, with an increasing need for compact, high-capacity systems in urban treatment plants.

The U.S. leads adoption due to:

Increasing industrial wastewater loads

Water reuse legislation

Scarcity in southwestern states

MBBRs are replacing aging activated sludge infrastructure, particularly in California, Arizona, and Texas.

China and Japan are scaling up MBBR deployment in industrial corridors to meet zero liquid discharge (ZLD) goals.

Germany is focusing on decentralized wastewater treatment with MBBR at the core of its smart water systems roadmap.

Compact footprint — ideal for retrofits and space-limited areas

Low sludge production

High treatment efficiency even with fluctuating influent

Easy to scale and integrate with MBR or activated sludge systems

Capable of handling high organic loads

Biofilm carriers susceptible to mineral scaling in hard water

Requires expert design to prevent carrier loss or clogging

Higher initial capex compared to basic lagoon systems

Hard water, rich in calcium and magnesium, can deposit scale on MBBR media, reducing microbial surface area and slowing biodegradation. This affects system efficiency and increases operational costs.

Companies like Applied Water Solutions are investing in scale-resistant carriers and anti-fouling technologies. Others are integrating pre-treatment softeners to prolong reactor life.

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

MBBR companies have lagged in brand marketing and distribution. But the tide is turning:

SEO-driven lead generation

B2B content strategies

Virtual product demonstrations

Firms are exploring:

Smart MBBR systems with real-time monitoring

Use of nematodes to enhance biofilm stability

Advanced aeration to optimize DO (dissolved oxygen) levels

Invest in R&D to solve hard water and scaling challenges

Focus on municipal and high-load industrial applications

Expand digital presence to educate engineers and operators

Monitor regulatory developments in North America and APAC

With climate resilience, industrialization, and circular economy practices accelerating, the MBBR market will increasingly become central to sustainable infrastructure. As more governments prioritize decentralized treatment, MBBR’s modular design and biological efficiency will play a pivotal role.

Get more details by ordering the complete report

| Stakeholder | Recommendation |

|---|---|

| Technology Firms | Develop anti-scaling media and integrate smart sensors |

| Municipal Bodies | Retrofit aging plants with modular MBBR solutions |

| Industrial Users | Leverage MBBR for lower discharge costs and compliance |

| Marketers | Increase content-driven campaigns to boost awareness |

Ongoing research in the MBBR market focuses on improving treatment efficiency, effluent quality, and adaptability for emerging contaminants like micropollutants removal. Innovations include advanced biochip media and techniques to optimize carrier filling, biofilm thickness, and solid retention for enhanced performance. Studies on hybrid MBBR systems, which integrate activated sludge processes, have demonstrated improvements in BOD removal, COD removal, and nitrogen removal. Emphasis is placed on understanding microbial communities, optimizing organic loading, and enhancing sludge separation processes. Additionally, precise monitoring of biochemical oxygen and chemical oxygen demand has become critical in regulatory compliance and system design. With water scarcity driving interest in water reuse, MBBR technology is increasingly seen as a viable, cost-effective, and environmentally responsible solution in the broader push for circular economy practices within the water treatment sector.

Safe and Secure SSL Encrypted