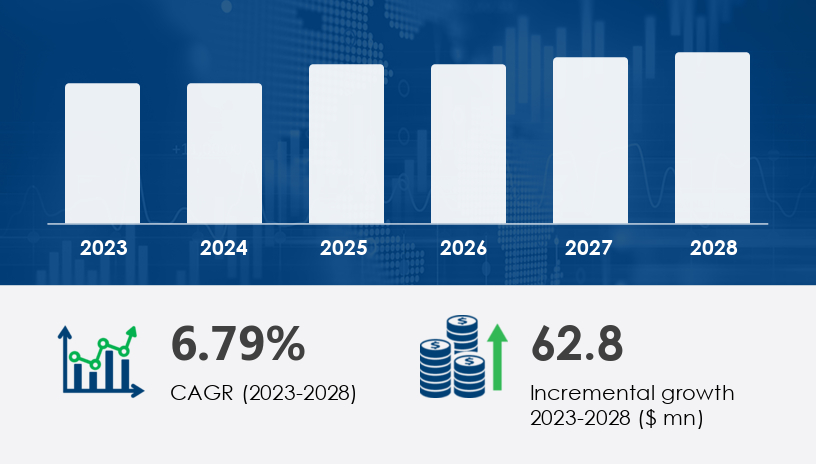

Grinding Robots Market Size 2024-2028

The grinding robots market is poised for substantial growth, with a forecasted increase of USD 62.8 million and a compound annual growth rate (CAGR) of 6.79% from 2023 to 2028. Grinding robots, also known as automated grinding systems, offer a variety of benefits over traditional CNC machines, including higher precision, greater productivity, and flexibility, which are particularly valuable in industries like automotive, aerospace, and medical. Technological advancements, such as machine learning algorithms and sensor integration, are driving these improvements, allowing robots to adapt to various grinding conditions in real time. Additionally, collaborative robots that allow human-robot interaction are enhancing the grinding process.

For more details about the industry, get the PDF sample report for free

Market Dynamics

The demand for automated machine solutions in manufacturing is a key driver of the grinding robots market. These robots are equipped with robotic arms, grinding tools, and advanced features like adjustable speeds, angles, and collision detection. Their increasing adoption in industries such as automotive, aerospace, and metal foundry is streamlining production processes by reducing human error and increasing efficiency. The market is also experiencing growth due to improvements in hardware, such as robotic vision systems that can adapt to varying workpiece geometries. However, small and medium enterprises (SMEs) face challenges with the high deployment costs of robots, and CNC grinding machines remain a preferred option due to their lower operational costs.

Key Market Drivers

- Applications of Robots in Complex Grinding Tasks: Increasing demand in industries like automotive, aerospace, and metal foundries, where grinding robots perform tasks such as deburring, grinding, and finishing.

- Technological Advancements: Enhanced vision systems, like laser vision sensors, are improving the precision of grinding tasks, driving market growth.

Significant Market Trends

- Improvements in Grinding Robot Vision Systems: Advancements in laser inspection and the use of laser vision sensors are ensuring efficient part inspection and precision grinding.

Major Market Challenge

- Preference for CNC Grinding Machines among SMEs: Despite the advantages of grinding robots, SMEs continue to favor CNC grinding machines due to lower costs and simpler operation.

Market Segmentation by Solution, End-User, and Geography

-

Solution Outlook

- Software

- Services

- Hardware

-

End-user Outlook

- Automotive sector

- Metals and machinery sector

- Aerospace and defense sector

- Others

-

Geography Outlook

- North America

- Europe

- The U.K.

- Germany

- France

- Rest of Europe

- APAC

- South America

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

Get more details by ordering the complete report

Key Players in the Market

- 3M Co

- ABB Ltd.

- Accord Corp.

- Acme Manufacturing

- Danbach Robot Jiangxi Inc.

- Daru Technology Suzhou Co. Ltd.

- FANUC Corp.

- Force Robots

- Heinz Berger Maschinenfabrik GmbH and Co. KG

- Kawasaki Heavy Industries Ltd.

- MESH Automation Inc.

- MIDEA Group Co. Ltd.

- Mitsubishi Electric Corp.

- NACHI FUJIKOSHI Corp.

- PushCorp Inc.

- Reichmann and Sohn GmbH

- SUHNER Schweiz AG

- Teqram BV

- Yaskawa Electric Corp.

- Seiko Epson Corp.

Recent Developments

- Technological Advancements: Grinding robots have benefitted from substantial technological enhancements, particularly in the areas of vision technology and machine learning. Vision systems, like laser inspection and laser vision sensors, are enabling more accurate and efficient grinding processes.

- Adoption in Various Industries: Increased use of grinding robots in automotive, aerospace, and metal foundry sectors is improving operational efficiency, production time, and product quality.