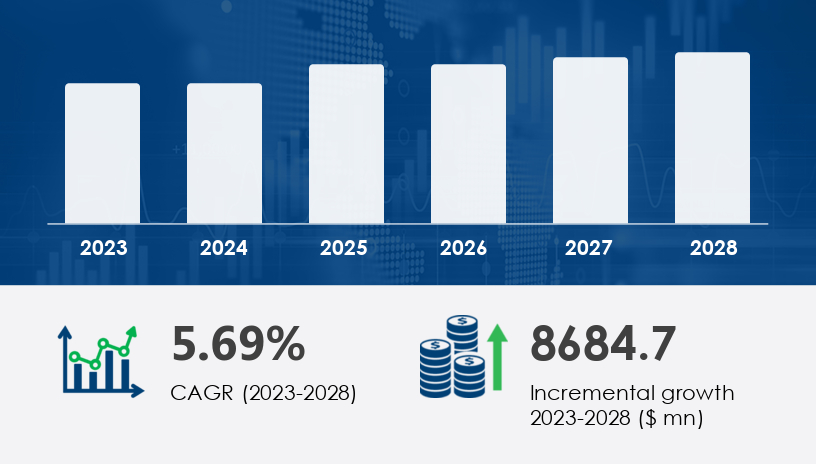

The friction products market is poised for substantial growth in the coming years, with a projected increase of USD 8.68 billion between 2024 and 2028, reflecting a compound annual growth rate (CAGR) of 5.69%. This growth trajectory is driven by a mix of evolving market trends, technological advancements, and increasing demands across various industries.

The global friction products market encompasses components critical to various industries, including automotive, aerospace, and industrial applications. These components—such as brake pads, linings, and clutches—play a fundamental role in ensuring the safe and efficient operation of vehicles and machinery. With the growing emphasis on sustainability and safety, the market is undergoing significant transformations.

For more details about the industry, get the PDF sample report for free

The Friction Products Market is growing rapidly due to advancements in braking technology and the increasing demand for high-performance, durable materials. Key components such as brake pads, brake shoes, clutch plates, and friction linings are integral in ensuring vehicle safety and efficiency. The industry is shifting toward asbestos-free materials, utilizing organic fibers, ceramic composites, and sintered metals in the production of friction discs and brake calipers. There is also a strong emphasis on wear resistance, heat resistance, and vibration damping to enhance the longevity of brake rotors and clutch systems. Brake-by-wire systems and adaptive braking technologies are revolutionizing the market, offering more precise control and improved performance in modern vehicles.

One of the primary drivers for the market's growth is the increasing demand for high-performance friction products, particularly in the automotive sector. As vehicle safety standards tighten and consumer preferences shift towards more fuel-efficient vehicles, manufacturers are responding with innovative solutions in brake systems and components. The integration of new materials and digitalization is significantly enhancing the performance and reliability of these products.

The friction products market is highly competitive, with numerous key players contributing to the industry’s growth. Companies are adopting a range of strategies, including strategic alliances, mergers and acquisitions, and technological advancements to enhance their market positions. Below are some of the leading players in the friction products market:

ABS Friction Inc.

AISIN CORP.

Akebono Brake Industry Co. Ltd.

Brembo Spa

Honeywell International Inc.

Miba AG

Robert Bosch GmbH

These companies focus on delivering high-quality, innovative products that meet the ever-evolving demands of automotive safety, industrial machinery, and aerospace applications.

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today

The friction products market can be segmented into three main categories: automotive, industrial, and aerospace. The automotive segment is by far the largest and is anticipated to experience substantial growth due to several factors.

Automotive Friction Products: These include brake pads, discs, and linings, which are essential in vehicle braking systems. The demand for lightweight and high-performance friction products is driven by the push for fuel efficiency and improved vehicle safety.

Industrial Friction Products: These products are crucial in machinery and equipment used in sectors like manufacturing, construction, and energy, where high resistance to heat and heavy loads is required.

Aerospace Friction Products: These are used in braking systems for aircraft and spacecraft, ensuring safety during landings and take-offs.

Others

Several key trends and drivers are significantly impacting the friction products market:

One of the key drivers for the growth of the friction products market is the increasing demand for high-performance braking systems in vehicles. As safety regulations become more stringent and consumer expectations rise, automakers are turning to advanced friction products that provide better stopping power, longer lifespan, and reduced wear and tear.

The integration of digitalization, robotic automation, and artificial intelligence (AI) in manufacturing processes is revolutionizing the production of friction products. These technologies enable companies to produce more precise, durable, and cost-effective components, meeting the evolving needs of industries like automotive and aerospace.

There is a significant shift toward asbestos-free friction products due to health and environmental concerns. Manufacturers are replacing traditional materials with eco-friendly alternatives like ceramic, sintered metals, and organic fibers, which offer improved performance without the associated health risks.

Despite the growth opportunities, the friction products market is grappling with the rise of counterfeit products. These imitation components, often produced with substandard materials, pose serious risks to vehicle safety and performance. The increasing prevalence of counterfeit products is a major challenge for businesses, prompting them to invest in product authenticity and consumer education.

Try a Free Report Sample Now

The APAC region is set to be the dominant contributor to the growth of the friction products market, primarily driven by the automotive industry's rapid expansion in countries like China, India, and Japan. The region’s focus on urbanization, electric vehicle adoption, and the modernization of public transportation infrastructure (especially in high-speed rail networks) is fueling demand for advanced friction products.

Urbanization: As cities expand, the need for reliable public transportation and vehicles grows, increasing the demand for friction products.

Automotive Industry Growth: The rise in both passenger vehicle sales and commercial vehicle demand in APAC countries is a major factor in the market’s expansion.

Electric Vehicles (EVs): The growing adoption of EVs, which require high-performance braking systems, is further driving demand.

Get more details by ordering the complete report

While the market is on an upward trajectory, there are challenges that could impact growth. As mentioned earlier, the prevalence of counterfeit friction products remains a significant threat. These products, often sold at lower prices, compromise safety and performance, undermining the market's integrity.

However, this challenge also presents an opportunity for companies to differentiate themselves by offering authentic, high-quality products. Businesses that invest in advanced technologies, improve product transparency, and build consumer trust will be best positioned to capitalize on the growing demand for friction products.

With the growing demand for eco-friendly materials and copper-free materials, manufacturers are focusing on lightweight materials and carbon fiber for friction plates and brake linings. The rise of smart friction and sensor integration with IoT devices is leading to the development of predictive maintenance solutions for brake systems. Noise reduction and thermal management are also key focus areas in the development of friction bands, friction rolls, and clutch facings. Bonded assemblies are increasingly used in high-performance brake linings, while innovations like double-floating caliper and sliding caliper designs further improve power transfer and braking efficiency. The integration of adaptive braking systems with sensor technology is enhancing the overall safety and functionality of friction products in various automotive applications.

Safe and Secure SSL Encrypted