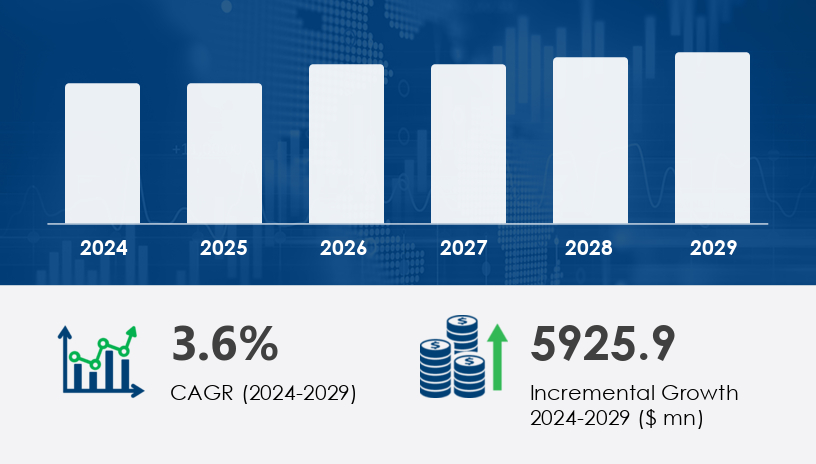

The global foundry equipment market is poised for substantial growth, with projections indicating an increase of USD 5.93 billion from 2024 to 2029, at a compound annual growth rate (CAGR) of 3.6%. This expansion is primarily driven by the accelerating adoption of industrial automation and the integration of simulation-based casting technologies. However, the industry faces significant challenges, including environmental concerns and the need for skilled labor.

For more details about the industry, get the PDF sample report for free

The Foundry Equipment Market is experiencing consistent growth, driven by increased demand for metal casting applications across industries such as automotive parts, aerospace components, and power generation. Key machinery such as molding machines, melting furnaces, and core making systems are widely used for producing aluminum castings, steel castings, and other cast metals. Developments in foundry machinery, including pouring machines and sand preparation units, support efficient casting processes while addressing evolving emission standards and energy efficiency requirements. Additionally, the integration of industrial automation and foundry robotics enhances productivity and worker safety through the use of protective gears and controlled handling of molten metals. The production of lightweight vehicles, generator castings, and turbine castings continues to stimulate market expansion, especially with advancements in die casting and precision casting methods.

Industrial Automation: The increasing implementation of automation technologies in foundries is enhancing productivity and reducing labor costs. Robotic systems and automated molding processes are becoming standard, leading to more efficient operations.

Simulation-Based Casting: Advanced simulation tools allow for the optimization of casting processes, improving the quality and precision of metal components while reducing material waste and energy consumption.

Sustainability Initiatives: There is a growing emphasis on eco-friendly practices, such as green casting and energy-efficient technologies, to meet stringent environmental regulations and reduce the carbon footprint of foundry operations.

Additive Manufacturing: The rise of 3D printing in metal casting is enabling the production of complex and lightweight components, particularly in the aerospace and automotive industries.

Advanced Alloys: The development of new metal alloys is enhancing the performance and durability of cast components, catering to the increasing demand for high-strength materials.

Digitalization and AI Integration: The incorporation of artificial intelligence and Internet of Things (IoT) technologies is facilitating real-time monitoring and predictive maintenance, leading to optimized production processes.

Energy Consumption and Waste Generation: Traditional foundry processes are energy-intensive and produce significant waste, posing sustainability challenges and increasing operational costs.

Skilled Labor Shortage: There is a critical need for trained professionals to operate advanced foundry equipment and manage complex production systems, necessitating investment in workforce development.

Regulatory Compliance: Adhering to evolving environmental regulations requires continuous investment in cleaner technologies and processes.

See What’s Inside: Access a Free Sample of Our In-Depth Market Research Report

Metal Casting: This segment is experiencing significant growth due to the increasing demand for metal parts in various industries, including automotive, aerospace, and construction.

Metal Heat Treatment: Advancements in heat treatment technologies are enhancing the mechanical properties of metal components, driving the demand for specialized equipment.

Automotive: The automotive industry is a major consumer of cast metal components, requiring high-quality and precision-engineered parts for engines, transmissions, and other critical systems.

Aerospace: The aerospace sector demands lightweight and durable components, leading to the adoption of advanced casting techniques and materials.

Machinery: Industrial machinery manufacturing relies on cast components for various applications, fueling the need for efficient foundry equipment.

Others

Semi-Automated Equipment: These systems offer a balance between manual labor and automation, providing flexibility and cost-effectiveness for medium-scale operations.

Manual Equipment: Traditional manual equipment remains prevalent in regions with limited access to advanced technologies, though its usage is declining.

Fully Automated Equipment: Fully automated systems are gaining popularity due to their efficiency and ability to reduce human error, particularly in high-volume production environments.

Market Share: APAC is estimated to contribute 49% to the global market growth during the forecast period.

Key Drivers: Rapid industrialization, urbanization, and infrastructure development are driving the demand for foundry equipment in countries like China, India, and Japan.

Strategic Focus: Investments in energy-efficient technologies and automation are essential to meet environmental standards and enhance competitiveness.

Market Dynamics: A well-established manufacturing sector and a focus on technological innovation are supporting market growth.

Challenges: High labor costs and stringent environmental regulations necessitate the adoption of advanced and sustainable foundry solutions.

Regulatory Landscape: Strict environmental policies are driving the adoption of green casting technologies and energy-efficient equipment.

Industry Collaboration: Strategic partnerships among key players are fostering innovation and expanding market reach.

Apex Tool Group LLC: Specializes in providing essential foundry equipment components, including pattern plates and alignment dowels.

Inductotherm Group: Offers advanced induction melting systems and related equipment for various metal processing applications.

Morgan Advanced Materials Plc: Provides high-performance materials and components for foundry applications, focusing on sustainability and innovation.

Technological Advancements: Companies are investing in research and development to enhance equipment efficiency and integrate automation technologies.

Sustainability Focus: Adoption of eco-friendly practices and compliance with environmental regulations are becoming central to business strategies.

Market Expansion: Strategic partnerships and mergers are enabling companies to expand their market presence and capabilities.

Get more details by ordering the complete report

Research in the foundry equipment market is increasingly focused on process optimization, defect reduction, and improving casting yield. Advanced techniques like simulation casting and modern furnace technology are helping manufacturers achieve greater accuracy and consistency in metal melting and alloy casting. Equipment like cooling drums, sand plants, and conveyor systems are being upgraded for efficiency, while cleaning solutions play a crucial role in post-casting refinement of machinery castings. Attention is also given to mold making, metal alloys, and their impact on high-precision applications. Growing trends include the use of high-performance equipment and smart systems for monitoring casting processes, ensuring quality in critical sectors. As sustainability becomes more important, the industry is working to align equipment capabilities with eco-friendly standards, especially for casting in sectors like aerospace and power generation.

The foundry equipment market is undergoing a transformation driven by technological advancements and shifting industry demands. Key implications for stakeholders include:

Investment in Technology: Continuous investment in automation, simulation-based casting, and additive manufacturing is crucial to remain competitive.

Focus on Sustainability: Adopting green casting techniques and energy-efficient technologies will be essential to meet regulatory requirements and reduce operational costs.

Workforce Development: Addressing the skilled labor shortage through training and development programs

Safe and Secure SSL Encrypted