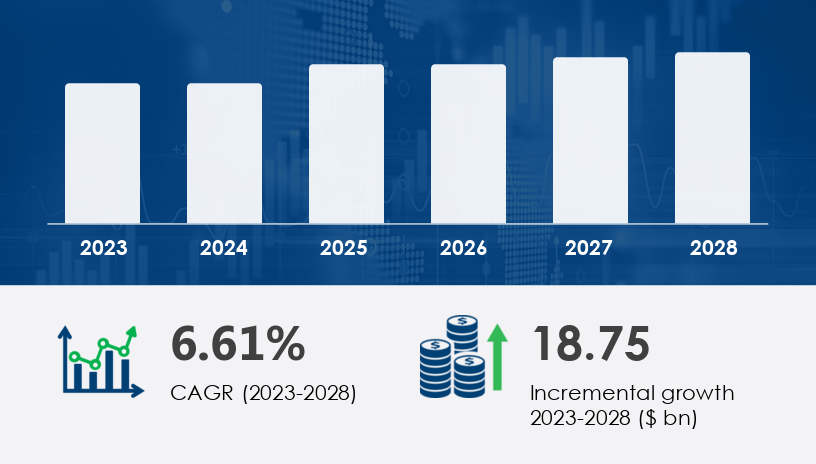

The flexible foam market is set to grow by USD 18.75 billion from 2024 to 2028, expanding at a CAGR of 6.61%. As demand for lightweight, durable, and cost-effective cushioning solutions increases, industries like automotive, furniture, and packaging are turning to flexible foam for next-generation comfort and performance.

For more details about the industry, get the PDF sample report for free

Flexible foam is a lightweight, soft, and resilient material primarily made from polyurethane. It’s widely used across industries for its cushioning, flexibility, and form-fitting capabilities. From mattresses and sofas to automobile seats and insulation panels, this material is synonymous with comfort and efficiency.

Consumer Goods: Surge in home furnishings, especially beds and chairs.

Transportation: Used extensively in seats, carpets, and insulation in cars and EVs.

Eco-Friendly Shift: Rising popularity of bio-based polyols for greener foam production.

Stat Snapshot:

As competition intensifies, companies are expanding capacities and refining product portfolios. Leading manufacturers are investing in bio-based foams and custom cushioning solutions to meet both environmental standards and consumer expectations.

BASF SE – Boosting sustainable foam solutions with bio-polyol innovations.

American Excelsior Inc. – Offers a diverse foam portfolio including viscoelastic and polyethylene foams.

Dow Chemical Co. – Pioneering high-performance polyurethane flexible foams.

Covestro AG, Huntsman International LLC, Greiner AG, and FXI – Dominant players expanding global footprints.

These firms are investing in new facilities, forming strategic partnerships, and tailoring solutions for furniture, transport, and green building applications.

Other key companies in thi smarket include:

Request Your Free Report Sample – Uncover Key Trends & Opportunities Today!

Flexible foam dominates the furniture and bedding segment, driven by its durability and ability to contour to body shapes, making it ideal for:

Mattresses & Pillows

Office Chairs

Sofas & Recliners

Carpet Underlays

Used extensively in:

Vehicle Seats

Armrests and Headrests

Eco-insulation for Electric Vehicles

Flexible foam offers shock absorption, lightweight durability, and formability, critical for:

Protective packaging

Hospital furniture

Child products and consumer goods

Polyurethane Flexible Foam: Dominates due to cost-efficiency and versatility, being widely used in bedding, automotive, and general-purpose furniture

Polyethylene Foam: Popular for lightweight packaging applications.

Polypropylene Foam: Increasingly used in automotive interiors for heat and impact resistance.

Others

The rise in demand for ergonomic, high-comfort mattresses and seating is the top driver. Consumers are prioritizing better sleep and personalized comfort, fueling flexible foam usage in high-end and budget furniture alike.

Global manufacturers are scaling operations:

BASF and Dow Chemical are expanding facilities to meet surging demand.

INOAC Corp. and Kaneka Corp. are boosting foam output in Asia and North America.

These expansions reflect rising foam demand in urban housing projects, vehicle manufacturing, and retail furniture sales.

Eco-conscious trends are reshaping the market:

Manufacturers are exploring bio-based alternatives to traditional petrochemical foams.

Castor oil-derived polyols are leading the way for green innovation.

Flexible foam is becoming an environmentally conscious choice in green buildings and automotive interiors.

The Flexible Foam Market is witnessing robust growth, primarily driven by the increasing demand for comfort and performance across industries such as furniture, automotive, and construction. Key materials like polyurethane foam, polyethylene foam, and polypropylene foam are widely used due to their versatility in applications such as foam mattresses, furniture cushions, and upholstery foam. Advanced variants like memory foam, high-resilience foam, and latex foam offer superior shape retention, foam durability, and ergonomic foam properties. The shift toward sustainability is also driving interest in bio-based foam, EcoComfort panels, polyurethane dispersions, and bio-based polyols. These materials are increasingly used in automotive seating—including seat cushions, headrest foam, and armrest foam—as well as in thermal insulation and acoustic insulation applications to enhance energy efficiency and passenger comfort.

APAC will contribute 41% of global growth, driven by:

Urbanization and increased spending on home furnishings

Rising automotive production, especially EVs

Expanding middle-class population demanding comfort and quality

China, Japan, and India are the dominant countries, thanks to active manufacturing bases and high consumer demand.

Regions like the US, Germany, and the UK are:

Emphasizing energy efficiency in buildings

Prioritizing sustainable product adoption

Experiencing demand for premium bedding and furniture

Growth here is driven by:

Industrial expansion

Uptick in real estate and commercial construction

Rising consumer awareness around product comfort and longevity

Get more details by ordering the complete report

Latex, memory foam, and natural fiber composites are gaining ground due to:

Superior durability or elasticity

Perceived environmental benefits

Regulatory pushes toward sustainable alternatives

Government mandates around VOC emissions, material recycling, and eco-labelling may increase compliance costs for foam producers.

Research analysis reveals a growing emphasis on specialized applications such as packaging foam, cushioning materials, and protective packaging, where performance attributes like shock absorption and foam recyclability are key. The market also highlights rising demand for anti-microbial foam, particularly in healthcare and hygiene-related consumer goods. Manufacturing techniques including slabstock foam and molded foam are tailored for diverse uses such as foam padding, foam seals, and foam gaskets. In the construction sector, insulation panels and construction insulation solutions benefit from the use of lightweight composites, contributing to structural strength without adding bulk. The increased adoption of comfort solutions across industries underlines the importance of foam versatility in delivering tailored, cost-effective, and durable materials that meet both consumer expectations and regulatory standards.

Safe and Secure SSL Encrypted