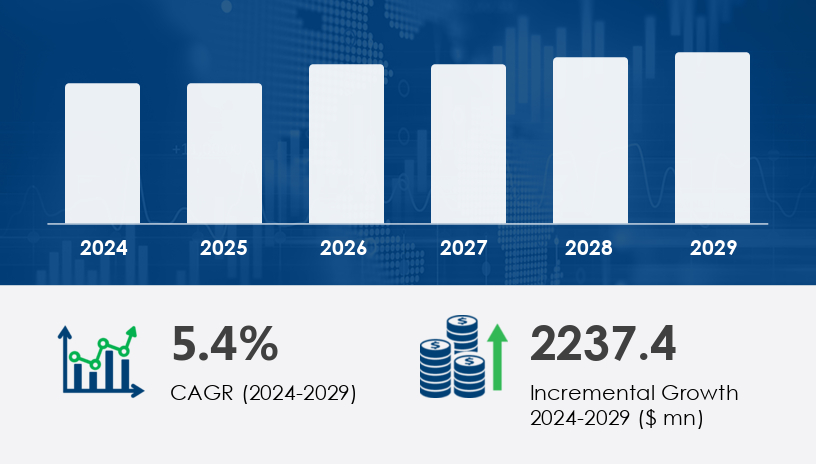

EMC test equipment market is set to add USD 2.24 billion in value by 2029, growing at a CAGR of 5.4% — driven by the explosive expansion of smartphones, electric vehicles, and 5G infrastructure.”In this 2025 Outlook and Comprehensive Guide, we dissect the surging electromagnetic compatibility (EMC) test equipment market, exploring the forces shaping its trajectory, from technological innovation to industry-specific demands. As digital ecosystems expand and device complexity increases, the strategic relevance of EMC testing — once seen as a compliance necessity — is now a business-critical differentiator.For more details about the industry, get the PDF sample report for free

Electromagnetic compatibility (EMC) refers to a system's ability to function as intended in its electromagnetic environment without causing or suffering from electromagnetic interference (EMI). In today’s hyperconnected world — spanning electric vehicles, smartphones, IoT devices, and military systems — ensuring electromagnetic immunity and emission control is non-negotiable.

“If electronics are the nervous system of modern technology, EMC testing is its quality control checkpoint,” says Dr. Meena Arora, Senior Analyst, Techwave Labs.

Smartphones are now engineering marvels, packed with antennas, sensors, and processors — all of which must co-exist harmoniously. EMC testing ensures these components don’t interfere with each other or external systems.

Case Study: A smartphone OEM in Shenzhen doubled its investment in in-house EMC testing after facing product delays due to failed FCC certifications in 2023. By shifting testing upstream, they slashed rework costs by 30%.

Autonomous driving, electric vehicles, and ADAS systems require robust internal communication networks. Technologies like MOST150, BroadR-Reach Ethernet, and vehicle-to-everything (V2X) demand flawless EMI performance.

“Electromagnetic interference in autonomous vehicles isn't just inconvenient — it's a safety hazard,” warns Dr. Rajan Pillai, EMC Systems Engineer at AutoSentry.

Get more details by ordering the complete report

Consumer Electronics: Fastest-growing due to mass smartphone adoption and smart home ecosystems.

Automotive: EMC is critical for EVs, infotainment, and safety systems.

Aerospace & Defense: Requires rigorous compliance due to high-risk environments.

Telecommunications: Driven by 5G infrastructure and IoT rollouts.

Others: Includes medical devices, industrial electronics.

EMI Test Receivers

Signal Generators

Spectrum Analyzers

Broadband Amplifiers

Others (e.g., RF probes, shielding materials)

In-house Laboratories: Popular among OEMs for pre-compliance.

Third-party Laboratories: Crucial for startups and SMEs.

Government: Standards enforcement and defense procurement.

Asia-Pacific (APAC) is poised to contribute 45% of global market growth between 2025 and 2029. Nations like China, Japan, India, and South Korea are hotspots for electronics manufacturing and R&D.

Key Drivers in APAC:

China’s dominance in consumer electronics export

Government push in India for local electronics manufacturing under “Make in India”

5G infrastructure expansion in South Korea and Japan

Other regions

For more details about the industry, get the PDF sample report for free

The Electromagnetic Compatibility (EMC) Test Equipment Market plays a critical role in ensuring electronic devices meet regulatory standards for electromagnetic interference and immunity. As modern devices increasingly integrate complex materials and systems, components like cable insulation, dashboard components, brake lines, fuel lines, and coolant hoses—many of which use synthetic rubber such as Nitrile rubber—require rigorous EMC testing. The use of butadiene copolymer and acrylonitrile polymer in these rubber components enhances chemical resistance, abrasion resistance, and tensile strength, which are crucial for maintaining performance under electromagnetic exposure. EMC test procedures also extend to kick panels, automotive seals, and fuel hoses, where oil-resistant rubber is necessary for durability. Moreover, the market supports testing for products such as O-rings, gaskets, construction seals, mining hoses, and metallurgy gaskets, all of which may interact with or be affected by electromagnetic fields. The adoption of EMC protocols in sectors utilizing insulation foam, rice rollers, and protective equipment further broadens the market's impact.

Rising awareness of compliance standards (FCC, CE, CISPR)

Integration of AI/ML for faster, smarter testing

Demand across multiple verticals: telecom, automotive, defense

High upfront costs for quality test systems

Price-sensitive customers opting for inferior equipment

Regulatory complexity across geographies

Get more details by ordering the complete report

AI is revolutionizing EMC diagnostics. Intelligent test equipment can now predict interference patterns, reducing test cycles and improving design time-to-market.

EMC testing is no longer limited to smartphones and cars. IoT sensors, wearables, drones, and smart meters are emerging categories demanding precision EMC testing.

Electric vehicles introduce high-voltage systems prone to EMI. EMC solutions are critical for motor controllers, battery management systems (BMS), and charging stations

High Equipment Costs

Advanced EMC setups (anechoic chambers, multi-axis turntables) can cost hundreds of thousands of dollars.

Regulatory Hurdles

Keeping up with evolving standards (EN, MIL-STD, ISO) requires constant updates and skilled compliance teams.

Shortage of Skilled Personnel

Certified EMC professionals are in short supply, delaying testing cycles and increasing operational bottlenecks.

OEMs should invest in modular, scalable EMC systems that grow with their product lines.

Testing labs must differentiate with faster turnaround times and AI-driven diagnostics.

SMEs can consider partnerships or shared facilities to offset equipment costs.

Regulatory bodies need to support standard harmonization and offer incentives for in-house compliance capabilities.

For more details about the industry, get the PDF sample report for free

As smart devices infiltrate every aspect of daily life — from refrigerators that tweet to vehicles that navigate autonomously — EMC compliance will transition from a technical checkbox to a core business enabler. Companies that treat EMC testing as a strategic asset, not just a regulatory hurdle, will find themselves better equipped to lead in innovation, safety, and customer satisfaction.

Invest Early: Early-stage EMC testing prevents costly post-production redesigns.

Go Portable: Adopt portable EMC testers to enable agile product validation.

Stay Certified: Align with international EMC standards to unlock global market access.

Leverage AI: Use machine learning to automate signal analysis and improve efficiency.

Research within the EMC Test Equipment Market highlights the growing need to assess advanced materials such as molded products, extruded products, conveyor belts, and high-performance composites like fast-curing NBR, specialty NBR, carboxylated NBR, and cross-linked powder. These materials are widely used in electronic and automotive systems requiring validation for electromagnetic compatibility. For instance, medical gloves and industrial gloves used in sensitive environments must pass EMC evaluations to prevent static interference. Other components—hydraulic gaskets, brake pads, tire treads, aerospace seals, and self-sealing tanks—are tested for performance stability when exposed to electromagnetic fields, thanks to their reliance on petroleum resistance, gas impermeability, and thermal resistance. With the increasing push for eco-friendly solutions, bio-based rubber is also being evaluated under EMC conditions to ensure it meets reliability standards. Additionally, adhesives sealants, high-pressure seals, and components requiring low-temperature flexibility are subject to EMC certification to ensure consistent functionality in varied operational environments.

Get more details by ordering the complete report

In a world increasingly governed by electronic integration, the electromagnetic compatibility (EMC) test equipment market stands as a pillar of reliability, safety, and regulatory alignment. With its projected USD 2.24 billion growth by 2029, the industry is not merely expanding — it’s evolving.

Safe and Secure SSL Encrypted