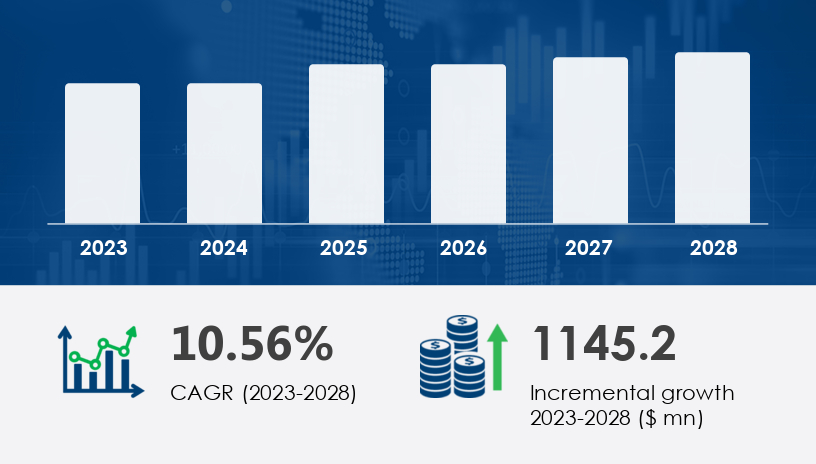

The cut-resistant gloves market is set for substantial growth, with a forecasted increase of USD 1.14 billion, driven by a compound annual growth rate (CAGR) of 10.56% between 2023 and 2028. This surge in demand is closely tied to the expanding emphasis on worker safety across labor-intensive sectors. From construction to healthcare, industries that face high risks of physical injury are adopting cut-resistant gloves as an essential part of their personal protective equipment (PPE). The 2025 outlook for this market highlights critical drivers and emerging trends that companies must consider to stay ahead of the curve.For more details about the industry, get the PDF sample report for free

Why are cut-resistant gloves in demand?

The growing focus on workplace safety is the primary factor behind the boom in the cut-resistant gloves market. Industries such as manufacturing, construction, metal fabrication, mining, and food processing are witnessing a rise in the need for gloves designed to prevent cuts, abrasions, and punctures caused by sharp objects and machinery. The statistics are clear: the global market is expanding as companies invest in better protective gear to reduce costly workplace injuries. According to recent estimates, hand injuries in industrial sectors can cost between USD 5,000 and USD 10,000 per incident, which further drives the demand for robust safety solutions.

By Type: The market is split between disposable and reusable gloves, with disposable gloves gaining significant traction due to their cost-effectiveness and ease of use. Reusable gloves, on the other hand, are valued in industries with heavy-duty applications, offering both enhanced durability and cost-efficiency.

By End-User: Industries such as automotive, metal fabrication, and machinery rely heavily on cut-resistant gloves to ensure the safety of workers exposed to high-risk environments. The healthcare and pharmaceutical sectors are also contributing to market growth, especially with the increased adoption of modular cleanrooms.

Safety Mandates: Increasing regulatory pressures to ensure worker safety in hazardous environments are driving the market. Organizations are increasingly adopting safety protocols that include the use of cut-resistant gloves.

Modular Cleanrooms: The rise in modular cleanrooms across sectors like healthcare and pharmaceuticals is a major trend, as these environments demand the highest standards of safety, where gloves play a crucial role in maintaining contamination-free zones.

Technological Advancements: The development of high-performance materials, such as Kevlar and Spectra fiber, has made cut-resistant gloves more durable and effective, ensuring that these gloves meet varying levels of protection.

Get more details by ordering the complete report

Looking toward the 2025 outlook, the future of the cut-resistant gloves market appears robust. The expanding industrial safety standards and the increasing penetration of advanced materials will further solidify the demand for these gloves.

Experts predict that the market will continue evolving as new materials like Dyneema fiber and metal mesh become more integrated into glove manufacturing. These materials offer superior protection without compromising flexibility or dexterity, essential for workers who need to perform intricate tasks.

Expert Opinion: "As we move forward, the ability to customize cut-resistant gloves to the specific needs of each industry will be a key differentiator in the market. Workers’ safety is no longer just about compliance—it’s about offering the right fit, comfort, and level of protection," says Jack Thompson, Safety Equipment Analyst at SafetyTech Innovations.

Despite the market's promising growth, several risks and challenges threaten to hinder its progress. Latex allergies remain a significant concern, as latex is a common material used in the production of gloves. For many individuals, latex can trigger allergic reactions ranging from skin irritation to more severe symptoms. To mitigate this risk, manufacturers are increasingly focusing on producing gloves from hypoallergenic alternatives, such as nitrile and PVC.

Case Study: In a real-world scenario, a large automotive manufacturing plant faced multiple employee complaints related to latex allergies. The company switched to nitrile-based cut-resistant gloves, resulting in a 30% reduction in allergy-related incidents. This shift not only enhanced worker safety but also improved overall productivity by minimizing absenteeism.

For more details about the industry, get the PDF sample report for free

Material Sensitivity: The challenge of allergic reactions to specific materials, such as latex, continues to be a significant obstacle. However, the shift towards nitrile and PVC is addressing this problem.

Cost Implications: While reusable gloves offer durability, their initial investment is higher compared to disposable alternatives, making them less appealing for short-term needs.

Customization: With a diverse range of industries requiring varying degrees of protection, the demand for highly customized gloves is on the rise. This creates challenges in both production and supply chain logistics.

The cut-resistant gloves market has gained significant traction as industries across the globe place an increasing emphasis on workplace safety and personal protective equipment (PPE). These gloves, which include high-performance options such as Kevlar gloves, Dyneema gloves, and polyethylene gloves, provide essential hand protection against sharp objects and workplace hazards. Offering varying degrees of cut protection, these gloves are classified by ANSI cut levels to meet specific safety standards. Applications span diverse sectors, including automotive gloves, metal fabrication gloves, construction gloves, and food processing gloves. With industries such as aerospace, oil and gas, and mining requiring specialized gloves for hand injury prevention, manufacturers have also developed advanced products like cryogenic gloves, aluminized gloves, and chemical-resistant gloves. In addition, ergonomic gloves, with their high dexterity and grip pattern designs, have become increasingly popular, ensuring a comfortable fit and enhanced worker safety.

Get more details by ordering the complete report

The competitive dynamics in the cut-resistant gloves market are defined by several key players who are leveraging strategic moves like partnerships, geographical expansion, and new product launches to gain market share.

Some of the leading companies in the space include:

3M Co.: Known for its diverse range of cut-resistant gloves, 3M has continued to innovate in glove design, providing comfort and enhanced grip for various industrial applications.

Ansell Ltd.: A pioneer in PPE, Ansell's cutting-edge technologies in glove manufacturing cater to sectors like aerospace, automotive, and metalworking.

Honeywell International Inc.: Honeywell’s commitment to safety gear and its strong market presence in industrial sectors places it among the top players.

The presence of these players, along with start-ups and small players, is intensifying competition. These companies are constantly refining their glove designs to meet evolving safety standards, adapting to the regional regulations, and introducing eco-friendly materials to capture the growing demand for sustainable PPE solutions.

For businesses looking to enter or expand within the cut-resistant gloves market, here are some strategic recommendations:

Embrace Customization: As industries become more specialized, the need for customized gloves with varying cut resistance levels, grip patterns, and ergonomic designs will increase. Companies should invest in R&D to develop tailored solutions.

Focus on Hypoallergenic Materials: To mitigate allergy risks, focus on the production of gloves made from nitrile or PVC. Emphasizing the hypoallergenic nature of products will not only enhance safety but also build customer loyalty.

Leverage E-Commerce: As the demand for PPE grows, e-commerce platforms will become critical in providing easy access to high-quality, custom-fit gloves that meet regulatory compliance.

For more details about the industry, get the PDF sample report for free

The demand for durable, reusable, and lightweight cut-resistant gloves is driven by the growing need for safety gloves in industrial sectors such as metalworking, glass manufacturing, and food processing. These gloves are often coated with nitrile, butyl, or abrasion-resistant materials to enhance their protective capabilities while maintaining flexibility. Stainless steel mesh gloves, known for their blade-resistant qualities, provide added security in high-risk environments. In addition to cut-proof gloves, puncture-resistant gloves and slash-resistant gloves are essential for workers exposed to sharp edges or potential hazards. With an increasing focus on hand safety, companies are also investing in disposable gloves, which offer convenience and flexibility for tasks that demand single-use protection. As the market expands, innovations in lightweight yet durable materials are expected to drive growth in protective gloves, offering better grip, comfort, and long-lasting protection for workers across multiple industries.

The cut-resistant gloves market is poised for continued growth, driven by the increasing demand for enhanced worker safety across high-risk industries. However, it’s crucial for businesses to keep pace with innovations in materials and manufacturing techniques, as well as navigate challenges related to allergic reactions and cost considerations. By focusing on customization, leveraging new materials, and aligning with industry-specific safety needs, companies can successfully meet the demand for cutting-edge protective gear.

Get more details by ordering the complete report

Safe and Secure SSL Encrypted