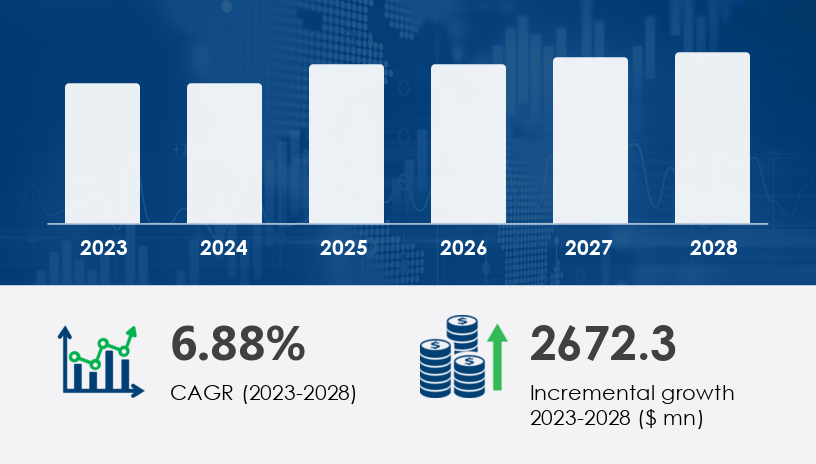

The CNC horizontal machining centers market is projected to grow by USD 2.67 billion between 2024 and 2028, registering a compound annual growth rate (CAGR) of 6.88%. The market expansion is driven by increasing demand for precision manufacturing and efficiency in industries such as construction, agriculture, metal fabrication, and manufacturing.CNC technology has transformed production processes by enabling multitasking machining centers to create complex parts with high accuracy. Additionally, the integration of remote monitoring allows real-time process optimization and predictive maintenance, enhancing productivity. The demand for smart manufacturing continues to shape market trends.The industry is also witnessing innovation through the rise of additive manufacturing and CNC turning. These advancements enable manufacturers to produce intricate components efficiently. However, the high initial investment in CNC horizontal machining centers poses challenges, particularly for small businesses and startups. Some companies are addressing this barrier through business incubators and collaborative partnerships to share resources and expertise.In the US, market competition is intensifying, leading to an increase in mergers and acquisitions among companies aiming to expand their presence and product portfolios. As the industry evolves, manufacturers focus on delivering advanced technologies and tailored solutions to meet customer demands.

For more details about the industry, get the PDF sample report for free

The automotive sector is anticipated to experience substantial growth during the forecast period. In the US, CNC horizontal machining centers are extensively used in the general engineering industry for manufacturing various engineering parts. These machines support industries such as oil and energy, heavy-duty machining, medical devices, electronic components, and hydraulic systems.

CNC horizontal machining centers play a crucial role in producing metal parts like bus bars, electrical contacts, terminals, lead frames, shields, and clips. These components are integral to vehicle systems, including chassis, fuel delivery systems, motors, engines, batteries, alternators, and braking mechanisms. The increasing production of cars, sports vehicles, and trucks in North America is expected to drive demand for CNC machining solutions.

Additionally, CNC horizontal machining centers are utilized in fluid power system manufacturing, including pneumatic and hydraulic systems. Essential components like drill bits and pumps rely on these machines for precision production. The growing demand for such systems in construction, manufacturing, and mining industries further propels market growth in the US.

Get more details by ordering the complete report

The CNC horizontal machining centres market is witnessing steady growth due to advancements in CNC machining technology and the increasing demand for precision machining equipment across industries such as aerospace, automotive, and metal fabrication. The integration of automated CNC systems and industrial automation machining solutions has significantly enhanced production efficiency, enabling manufacturers to optimize workflows and reduce downtime. Additionally, high-speed machining centres equipped with multi-axis CNC machines are gaining traction, allowing for intricate CNC milling processes that cater to the needs of aerospace CNC machining and automotive CNC machining applications. The evolution of horizontal machining tools and CNC horizontal spindle design is further driving market expansion, providing enhanced stability and accuracy for complex metalworking operations. As CNC machining market trends continue to shift towards digitalization and automation, companies are focusing on smart CNC technology to improve productivity while minimizing operational costs.

The adoption of heavy-duty CNC machines and metalworking CNC equipment is reshaping modern manufacturing by offering greater flexibility and precision in CNC machine tooling. The increasing focus on CNC machining efficiency has led to the development of advanced manufacturing solutions, incorporating AI-driven analytics for predictive maintenance and performance optimization. CNC horizontal machining centres are becoming essential in various industries due to their ability to handle complex geometries and high-performance materials with minimal human intervention. Additionally, advancements in CNC machine maintenance ensure prolonged machine lifespan and reduced downtime, enhancing overall productivity. Manufacturers are leveraging CNC horizontal spindle design for superior cutting capabilities, making them a preferred choice for applications requiring high precision. With the rise of smart CNC technology, businesses are investing in CNC machining technology that supports real-time monitoring and adaptive control systems, ensuring seamless operations across various production lines.

Safe and Secure SSL Encrypted