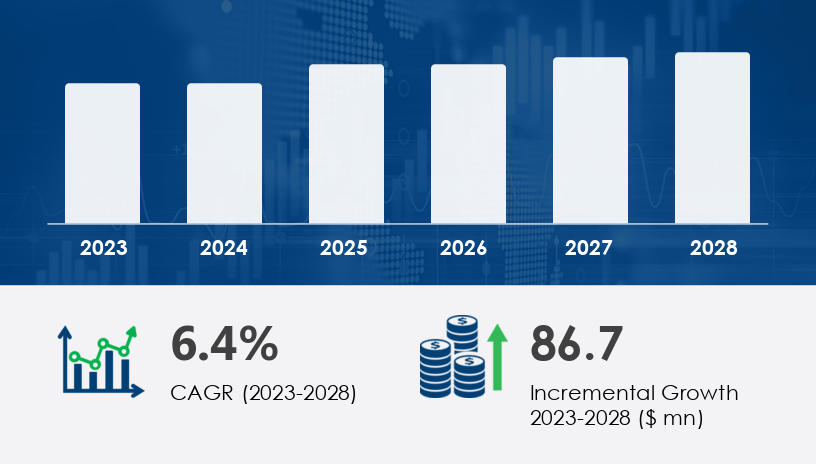

The balsa core materials market is undergoing transformative growth, spurred by robust developments in shipbuilding and the renewable energy sector. Projected to grow at a CAGR of 6.4% between 2023 and 2028, the market is set to expand by USD 86.7 million, driven by the increasing demand for lightweight, high-strength composite materials across marine, aerospace, and wind energy applications.For more details about the industry, get the PDF sample report for free

A primary engine of growth is the expansion of the shipbuilding industry, which is increasingly reliant on lightweight and high-shear strength materials like balsa core for the construction of efficient vessels. This demand aligns with the global shift toward fuel-efficient and low-emission marine transportation. Balsa wood's buoyancy, low density, and resistance to water absorption make it an ideal core material for decks, floors, and interior structures in modern ships.

The wind energy sector is another high-growth arena for balsa core materials. With balsa wood being a sustainable, renewable resource, its integration into wind turbine blades and rotor panels complements the global push toward clean energy. These materials offer not just structural strength but also align with the objectives of reducing carbon emissions and achieving energy sustainability.

One of the most notable trends shaping the market is the rising number of offshore wind farm installations. Offshore farms offer higher operational efficiency and are less environmentally intrusive compared to onshore projects. This transition is reinforcing the demand for rigid and contoured EndGrain balsa structures, which provide lightweight stiffness and shock absorption essential for offshore wind applications.

In the construction sector, hybrid core systems that integrate balsa with recyclable alternatives like polyethylene terephthalate (PET) are gaining traction, adding to the material’s eco-friendly appeal. Moreover, balsa's application in solar panels and sports equipment underscores its versatility beyond traditional industrial use.

Despite these drivers, the balsa core materials market faces intense competition from substitutes such as foam cores (PVC, PET, SAN) and aluminum or Nomex honeycomb structures. These alternatives offer competitive advantages, including better moisture resistance, lower cost, and easier processing. The growing adoption of these synthetic alternatives, particularly in wind energy and aerospace, poses a notable challenge to traditional balsa usage.

Balsa's susceptibility to moisture and its higher cost structure compared to some synthetic materials continue to limit its wider adoption, especially in cost-sensitive or high-moisture environments.

Get more details by ordering the complete report

The market is segmented into monolayer and multilayer balsa core materials. Among these, the monolayer segment is forecasted to experience substantial growth during the forecast period. Valued at USD 139.60 million in 2018, monolayer balsa is celebrated for its excellent bonding properties, insulation, fire resistance, and noise reduction capabilities. It is widely used across industries such as:

Wind energy (turbine blades, composite panels)

Aerospace (aircraft, helicopters)

Marine (boats, hovercraft)

Automotive (interior structures, engine covers)

Construction (floor panels)

Medical and sports equipment (shock absorption applications)

Wind Energy: The largest and fastest-growing segment, driven by the global renewable energy push and offshore wind installations.

Aerospace: Utilizes balsa in composite panels for aircraft and helicopters due to its strength-to-weight ratio.

Marine: Boats and hovercraft incorporate balsa for its buoyancy and stiffness.

Others: Including construction, transportation, and recreational applications.

Estimated to contribute 37% of global market growth.

China and India lead with heavy investment in renewable energy and marine infrastructure.

Key markets include Germany and France, where aerospace and offshore wind installations are prominent.

The U.S. continues to be a major consumer, driven by advancements in renewable energy, aerospace, and shipbuilding.

Emerging adoption in construction and transportation sectors due to growing industrialization and demand for sustainable materials.

For more details about the industry, get the PDF sample report for free

The Balsa Core Materials Market is experiencing notable growth due to the rising demand for lightweight composites and eco-friendly materials across various high-performance sectors. Balsa core—derived from balsa wood—is a popular choice for core materials in industries such as wind energy, marine, aerospace, and construction. Its superior insulation properties and function as a high-strength core make it ideal for wind turbine blades, marine hulls, aircraft structures, and lightweight vehicles. In wind energy, turbine blade materials like balsa composite panels and balsa honeycomb are critical for building durable and efficient turbine blade cores. Similarly, boat hull materials, marine composites, and shipbuilding materials benefit from the buoyant and resilient nature of end-grain balsa. The trend toward sustainable materials and bio-based composites is further propelling the market, especially for lightweight panels used in construction composites and transportation composites.

Leading companies are engaging in strategic alliances, mergers and acquisitions, and geographic expansion to strengthen their market positions:

Adhesive Technologies NZ Ltd. – Specializes in end-grain and micro-honeycomb balsa, catering to aerospace, marine, automotive, and construction industries.

Allred and Associates Inc.

Bodotex AS

Carbon Core Corp.

Composite Envisions LLC

CoreLite

Diab Group

Gurit Holding AG

I Core Composites LLC

LBI Inc.

Nord Compensati Srl

Schweiter Technologies AG

Sicomin Epoxy Systems

Specialized Balsa Wood LLC

These players are focusing on innovative product development and sustainability practices, such as incorporating recyclable PET hybrids and leveraging sustainable forestry resources for balsa procurement.

Get more details by ordering the complete report

Research into balsa core technologies emphasizes innovations in composite structures and aerospace sandwich panels, where balsa wood core is widely used for its lightweight insulation and durability. Advancements in resin infusion techniques allow manufacturers to create high-performance composite materials such as sandwich panels, structural panels, and aircraft panels with exceptional mechanical properties. The market is also seeing a surge in demand for construction panels, boat decks, and balsa sheets tailored for complex marine applications and aerospace composites. The increasing focus on wind blade manufacturing and offshore wind energy projects is further enhancing the role of balsa composite cores. With growth in aerospace components and wind energy components, the integration of balsa panels into lightweight insulation applications ensures both performance and environmental sustainability. Research continues to explore optimized core designs, including high-stiffness cores and balsa-based composite cores, aimed at enhancing the structural integrity of advanced composite systems.

The market for balsa core materials continues to expand, riding the wave of green energy initiatives, lightweight vehicle mandates, and the resurgence in global marine transport. Despite the rise of synthetic substitutes, innovations in hybrid systems and the sustainability profile of balsa wood provide a competitive edge. The U.S. market, in particular, remains central due to its industrial diversity and renewable energy goals.

For more details about the industry, get the PDF sample report for free

Safe and Secure SSL Encrypted