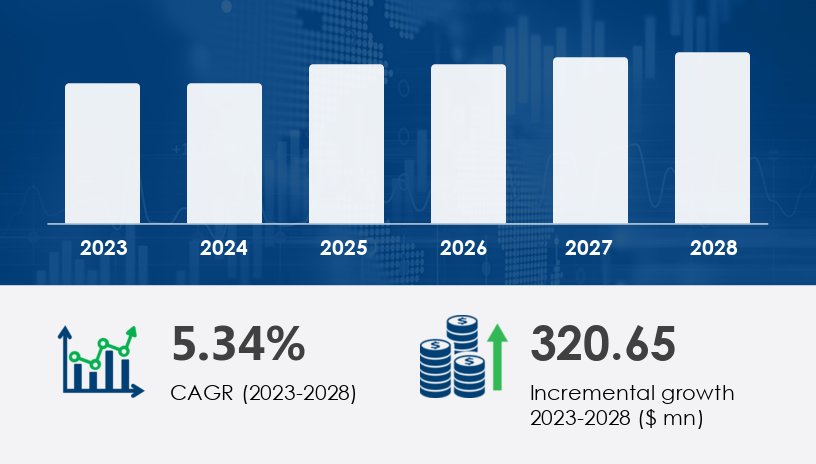

Aerospace Adhesive and Sealants Market Size 2024-2028

The aerospace adhesive and sealants market is forecast to grow by USD 320.65 billion at a CAGR of 5.34% between 2023 and 2028. This significant growth is driven by multiple factors, including the increasing number of air passengers globally, which has escalated the demand for new aircraft as well as the need for maintenance, repair, and overhaul (MRO) services. Various adhesives such as silicones, polyurethanes, polysulfides, acrylics, cyanoacrylates, hot melts, reactive, solvent-borne, UV-cured, and water-borne adhesives are key materials used in the industry. Moreover, growing investments in expanding adhesive production are responding to the rising demand from aerospace manufacturers. However, the market faces challenges due to stringent regulatory standards that affect adhesive and sealant production, raising complexity and costs.

For more details about the industry, get the PDF sample report for free

Market Segmentation

The aerospace adhesives and sealants market is segmented by technology, end-user, and geography. The report provides insights into each segment, with growth projections from 2024 to 2028.

By Technology:

- Water-based: Water-based adhesives and sealants, estimated to experience significant growth during the forecast period, are eco-friendly and reduce hazardous air pollutants. They are often used for bonding and sealing aircraft components in manufacturing processes.

- Solvent-based

- Others

By End-user:

- Commercial

- Military

- General aviation

By Geography:

- North America

- APAC

- Europe

- South America

- Middle East and Africa

Market Dynamics

Drivers:

- Increasing air passenger numbers globally: The rise in air travel has significantly boosted the demand for new aircraft and MRO services.

- Growth in aircraft manufacturing and MRO activities: Increasing aircraft production, especially in regions like the US, is expanding the market.

- Emphasis on lightweight materials: The need to reduce aircraft weight for improved fuel efficiency is a major factor driving the market.

Trends:

- Rising investments to boost adhesive production: Companies like Henkel are expanding their adhesive production capacities to meet the growing demand. Henkel’s Kunpeng plant, for instance, focuses on increasing the production of high-performance adhesives like silicone and polyurethane.

- Growing focus on eco-friendly solutions: Water-based adhesives are gaining popularity due to their environmental benefits, being a sustainable choice for aircraft manufacturing.

Get more details by ordering the complete report

Challenges:

- Stringent regulatory standards: Regulatory bodies like the FAA impose stringent requirements for adhesives and sealants, making it challenging for manufacturers to comply with safety and reliability standards while keeping costs manageable.

- Complexity and cost of compliance: Meeting safety regulations increases production costs and complicates manufacturing processes.

Key Players

The aerospace adhesive and sealants market is highly competitive, with several key players operating in the market. Some of the prominent companies include:

- 3M Co.

- Akzo Nobel NV

- Antala S.L.

- Beacon Adhesives Inc.

- Bostik Ltd.

- Dow Chemical Co.

- Dymax Corp.

- Henkel AG and Co. KGaA

- Hernon Manufacturing Inc.

- Hexcel Corp.

- Holcim Ltd.

- Huntsman International LLC

- L and L Products Inc.

- Lanxess AG

- Master Bond Inc.

- Permabond LLC

- PPG Industries Inc.

- Sika AG

- Solvay SA

- Vitrochem Technology

These players are investing in strategic partnerships, product launches, and geographical expansions to maintain a strong market position. For example, Henkel’s new Kunpeng facility aims to enhance its production and supply capabilities for high-performance adhesives in aerospace.

Future Market Insights

The aerospace adhesive and sealants market is poised for sustained growth through 2028, driven by rising air passenger numbers, technological advancements, and the demand for lightweight, high-performance adhesives in aircraft manufacturing. As aerospace companies continue to innovate with eco-friendly materials and address regulatory challenges, the market will remain dynamic and competitive.