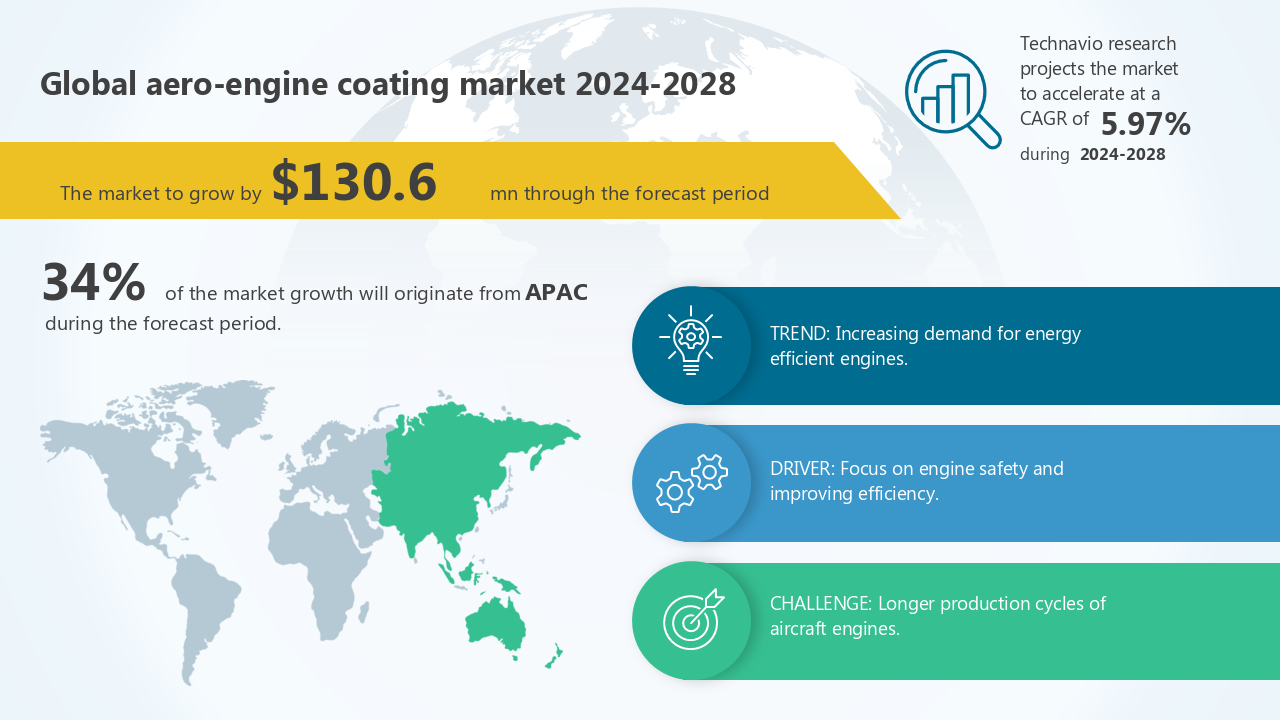

Aero-Engine Coating Market 2024-2028: Size and Longer production cycles of aircraft engines

The aero-engine coating market size by Application (Commercial aircraft, Military aircraft, and Others), Formulation (Powder coatings, Liquid coatings, and Wired coatings), and Geography (North America, Europe, APAC, Middle East and Africa, and South America), is forecast to increase by USD 130.6 million. The market is expected to grow at a CAGR of almost 5.97% between 2024 and 2028.

- The aero-engine coating market faces challenges due to the intricacies and high stakes involved in aircraft engine testing. A single engine fault or operational issue can trigger costly recalls and groundings, necessitating extensive redesigns and replacements. These delays significantly impact the demand for aero-engine coatings and related materials, potentially hindering market expansion during the forecast period. Rolls-Royce's Trent 1000 engine development and subsequent technical glitches serve as prime examples of this complex dynamic.

- The Aero-Engine Coating Market represents a significant business opportunity, driven by the increasing demand for fuel efficiency and durability in aircraft engines. Coatings enhance engine performance by reducing friction, protecting against corrosion, and improving thermal insulation. Market growth is further fueled by advancements in nanotechnology and the increasing adoption of ceramic coatings. These innovations offer enhanced durability, reduced maintenance costs, and improved engine efficiency. Overall, the Aero-Engine Coating Market is a strategic investment for businesses seeking to optimize engine performance and reduce operational expenses.

Access the full report to know who are the other key countries segment-wise forecast and historic data

Some of the Key Companies:

- A and A Thermal Spray Coatings

- Akzo Nobel NV

- APS Materials Inc.

- Argosy International Inc.

- BASF SE

- BryCoat Inc.

- Dow Chemical Co.

- Henkel AG and Co. KGaA

- Hentzen Coatings Inc.

- Hohman Plating

- IHI Corp.

- Indestructible Paint Ltd.

- Lincotek Surface Solutions SPA

- Linde Plc

- Mankiewicz Gebr. and Co.

- OC Oerlikon Corp. AG

- PPG Industries Inc.

- Sequa Corp.

- The Sherwin Williams Co.

- Zircotec Ltd.

Contacts

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email: media@technavio.com

Website: www.technavio.com/